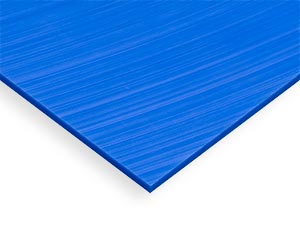

Virgin UHMW is a relatively low cost abrasion, impact, and chemically resistant material.

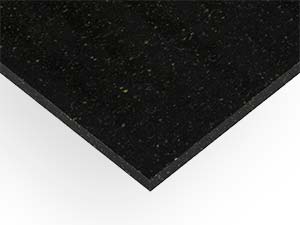

Black UHMW sheet, virgin grade, for general purpose use.

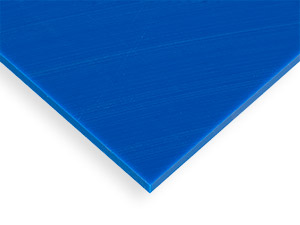

Low friction virgin UHMW resists chemicals and impacts and extends part life.

Low friction virgin UHMW resists chemicals and impacts and extends part life.

Low friction virgin UHMW resists chemicals and impacts and extends part life.

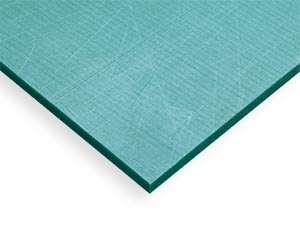

Reprocessed UHMW is recommended for less demanding applications versus virgin.

Reprocessed UHMW is recommended for less demanding applications versus virgin.

UHMW-PE anti-static can move products more safely in potentially volatile environments.

Superior Use in Protecting Chain Guides, Sliding Strips, Rollers and Corner Wear Bends

Tivar® HOT maintains key performance properties in an extended temperature range.

Premium lining material for bulk material handling.

Tivar® DrySlide is an anti-static plastic sheet with self-lubricating properties.

IPX 2000 is an advanced, engineered polyethylene that has greater benefits than standard UHMW.

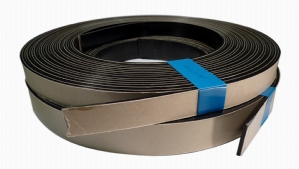

50ft Rolls of Adhesive-Backed Anti-Static UV Stable Pressure-Sensitive Tape.

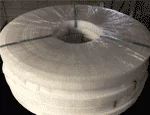

Non-Adhesive UHMW-PE Wear Strip Rolls.

50ft Rolls of Easy to Apply (ETA) Adhesive Backed UHMW Tape.

Ideal solution for conveying applications where long lengths with no seams are preferred.

Ideal solution for conveying applications where long lengths with no seams are preferred.

Rustication strips for smooth and even architectural reveals.

Virgin UHMW is a relatively low cost abrasion, impact, and chemically resistant material.

A FDA compliant blue colored UHMW rod.

Reprocessed UHMW is recommended for less demanding applications versus virgin.

Reprocessed UHMW features the benefits of virgin UHMW at a more cost-effective price.

Reprocessed UHMW features the benefits of virgin UHMW at a more cost-effective price.

Reprocessed UHMW features the benefits of virgin UHMW at a more cost-effective price.

Virgin grade black UHMW rod stock has good wear, chemical, & impact resistances.

UHMW is a relatively low cost abrasion, impact, and chemically resistant material.

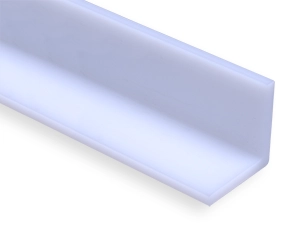

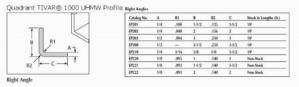

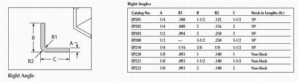

UHMW angles are an economical way to reduce the abrasion of metal parts & extend part life.

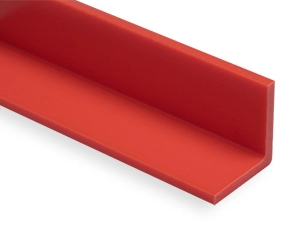

Reprocessed UHMW angles are an economical way to reduce abrasion of metal parts & extend part life.

Reprocessed UHMW angles are an economical way to reduce abrasion of metal parts & extend part life.

Reprocessed UHMW angles are an economical way to reduce abrasion of metal parts & extend part life.

Reprocessed UHMW angles are an economical way to reduce abrasion of metal parts & extend part life.

Reprocessed UHMW angles are an economical way to reduce abrasion of metal parts & extend part life.

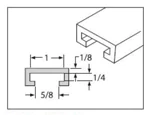

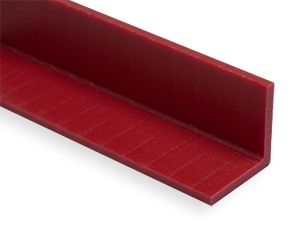

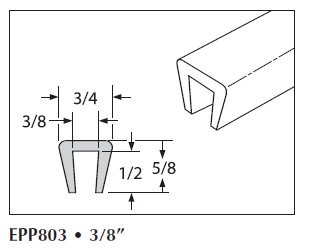

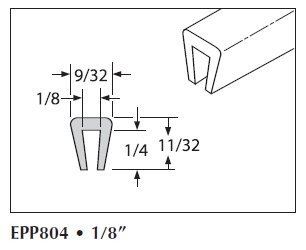

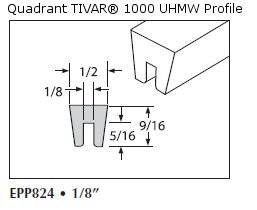

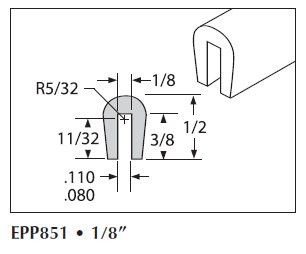

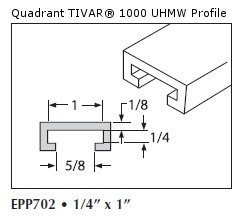

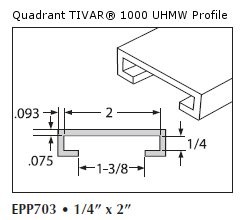

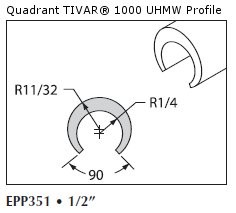

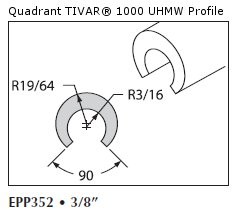

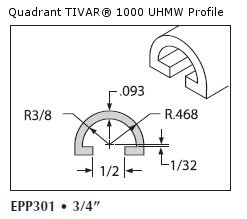

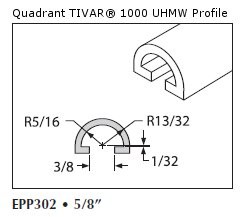

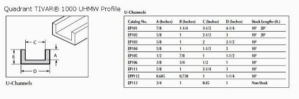

Fast economical way to turn an abrasive metal component into a long wearing, non marring component.

Fast economical way to turn an abrasive metal component into a long wearing, non marring component.

Fast economical way to turn an abrasive metal component into a long wearing, non marring component.

Fast economical way to turn an abrasive metal component into a long wearing, non marring component.

Fast economical way to turn an abrasive metal component into a long wearing, non marring component.

Fast economical way to turn an abrasive metal component into a long wearing, non marring component.

Fast economical way to turn an abrasive metal component into a long wearing, non marring component.

Fast economical way to turn an abrasive metal component into a long wearing, non marring component.

Fast economical way to turn an abrasive metal component into a long wearing, non marring component.

Fast economical way to turn an abrasive metal component into a long wearing, non marring component.

Fast economical way to turn an abrasive metal component into a long wearing, non marring component.

Fast economical way to turn an abrasive metal component into a long wearing, non marring component.

Fast economical way to turn an abrasive metal component into a long wearing, non marring component.

Fast economical way to turn an abrasive metal component into a long wearing, non marring component.

Fast economical way to turn an abrasive metal component into a long wearing, non marring component.

Fast economical way to turn an abrasive metal component into a long wearing, non marring component.

Includes a 6x6" sample of ABS, Noryl, Polycarbonate, and UHMW.

Includes a 6x6" sample of Acetal, Nylon, UHMW, and a 3x3" sample of PTFE.

6x6" sample of ABS, Acetal, Acrylic, HDPE, PVC, UHMW, and 3x3" sample of PTFE.

6x6" sample of ABS, Acetal, Acrylic, Nylon, PVC, UHMW, PET, and a 3x3" sample of PTFE.

Plastic cutting bits by Onsrud are an industry standard in quality.

Plastic cutting bits by Onsrud are an industry standard in quality.

Saw blades that offer premium performance on hard and soft plastics.