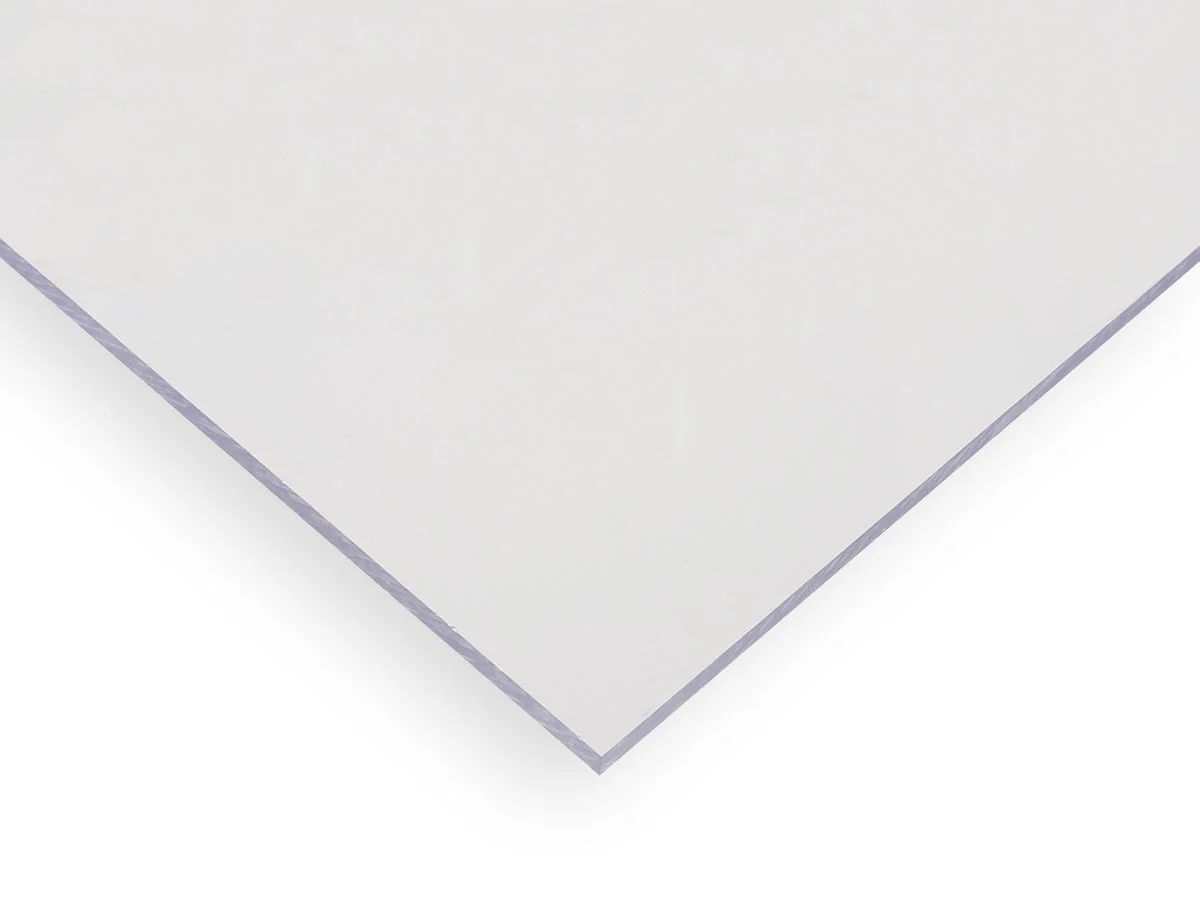

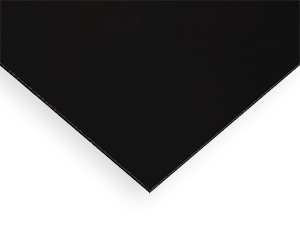

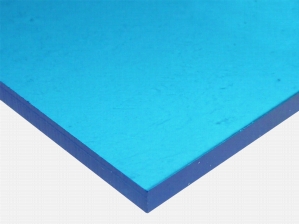

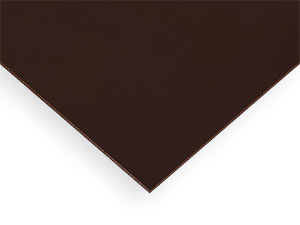

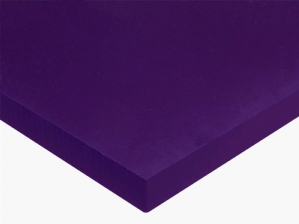

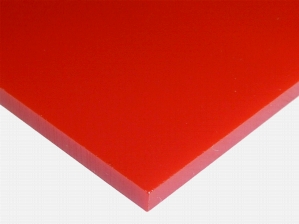

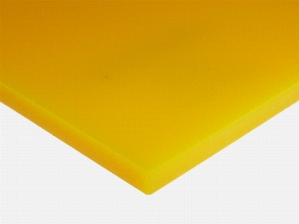

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

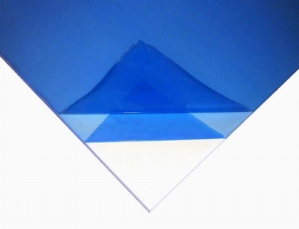

Extruded Acrylic has moderate properties, easy handling and processing, and low cost.

Extruded Acrylic has moderate properties, easy handling and processing, and low cost.

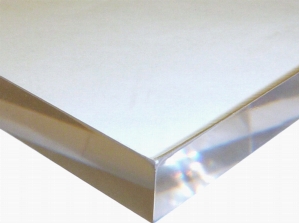

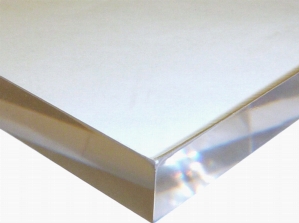

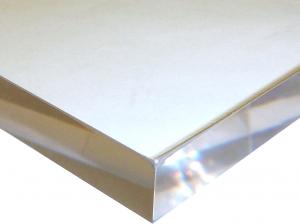

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, & is lightweight.

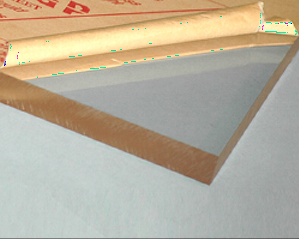

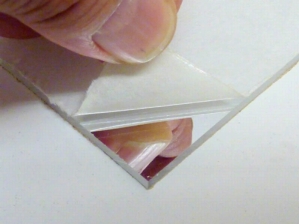

Cast acrylic sheet with abrasion resistant coating on both sides. Lightweight & scratch resistant.

Cast acrylic sheet with abrasion resistant coating on both sides. Lightweight & scratch resistant.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Premier framing grade acrylic sheet.

Museum-quality UV protected acrylic sheet.

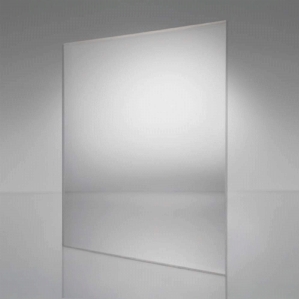

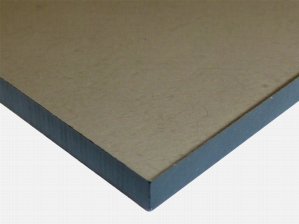

P99 Acrylic has a matte finish, non-glare surface, which minimizes reflection for glare-free viewing.

Non-glare Acrylic has a matte finish, non-glare surface, which minimizes reflections.

Clear continuous cast acrylic sheets. Also formerly known as Lucitelux.

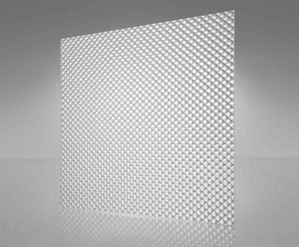

Plaskolite Optix prismatic acrylic lighting panels offer excellent efficiency & glare control.

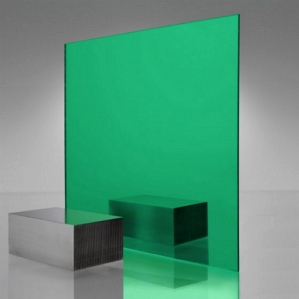

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, & is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, & is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, & is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

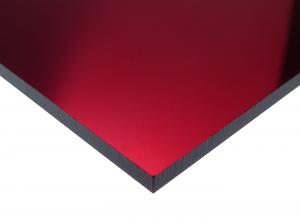

Acrylic plexiglass mirror: 17 times stronger than glass, great clarity, durability, & lightweight.

Acrylic plexiglass mirror: 17 times stronger than glass, great clarity, durability, & lightweight.

Acrylic plexiglass mirror: 17 times stronger than glass, great clarity, durability, & lightweight.

Acrylic plexiglass mirror: 17 times stronger than glass, great clarity, durability, & lightweight.

Acrylic plexiglass mirror: 17 times stronger than glass, great clarity, durability, & lightweight.

Acrylic is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

PMMA, Poly(methyl methacrylate). Extruded Acrylic has moderate properties & easy handling.

PMMA, Poly(methyl methacrylate).

PMMA, Poly(methyl methacrylate).

Our sneeze guard cleaning and disinfecting kit has everything needed to safely clean sneeze guards.

A superior solution for sanitizing sneeze guards - effective against COVID-19.

Comes with Brillianize Plastic Cleaner & Polish as well as two microfiber towels.

Perfect for dusting, cleaning and polishing easy to scratch surfaces.

Perfect for dusting, cleaning and polishing easy to scratch surfaces.

10" x 18" microfiber dry cleaning cloth for static and dust control.

2oz bottles of Novus 1, 2, and 3 as well as a microfiber towel and cleaning wipes.

Gently cleans without scratching and leaves a smooth finish that resists finger marks and fogging.

Removes fine scratches, haziness and abrasions from most plastics

Restore older, deeply damaged acrylic and plastic fixtures.

WARNING: The products on this page can expose you to chemicals including Ethyl acrylate, CAS 140-88-5, which are known to the State of California to cause cancer. For more information go to www.p65warnings.ca.gov.