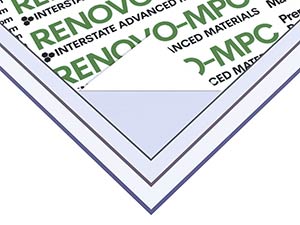

Polycarbonate Renovo-MPC is a transparent post-consumer reprocessed polycarbonate sheet.

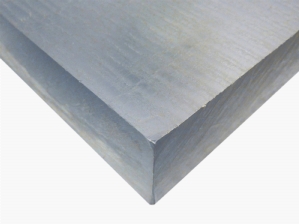

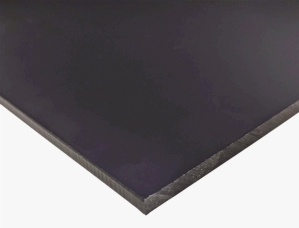

Polycarbonate is a versatile, tough, durable plastic used for a variety of applications.

Durable & flexible polycarbonate film can be thermoformed, molded, or die-cut into complex shapes.

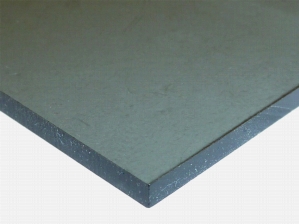

Polycarbonate AR is an abrasion and enhanced UV-resistant sheet.

High impact strength, dimensional stability, and the lowest internal stress and inclusion levels.

Polycarbonate is a versatile, tough, durable plastic used for a variety of applications.

Polycarbonate is a versatile, tough, durable plastic used for a variety of applications.

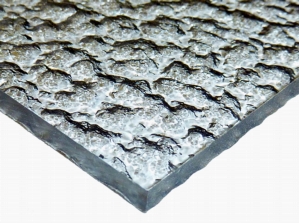

Pebble textured polycarbonate lets light in while obstructing the view of objects behind it.

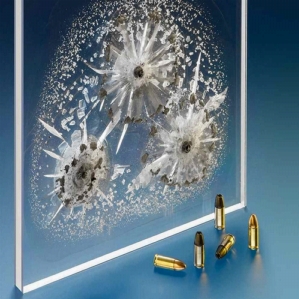

Plaskolite® Hygard BR withstands extreme threats with no compromises to performance.

Plaskolite Hygard® CG withstands extreme threats with no compromises to performance.

PALSHIELD® is engineered to meet a variety of forced entry and ballistic test standards.

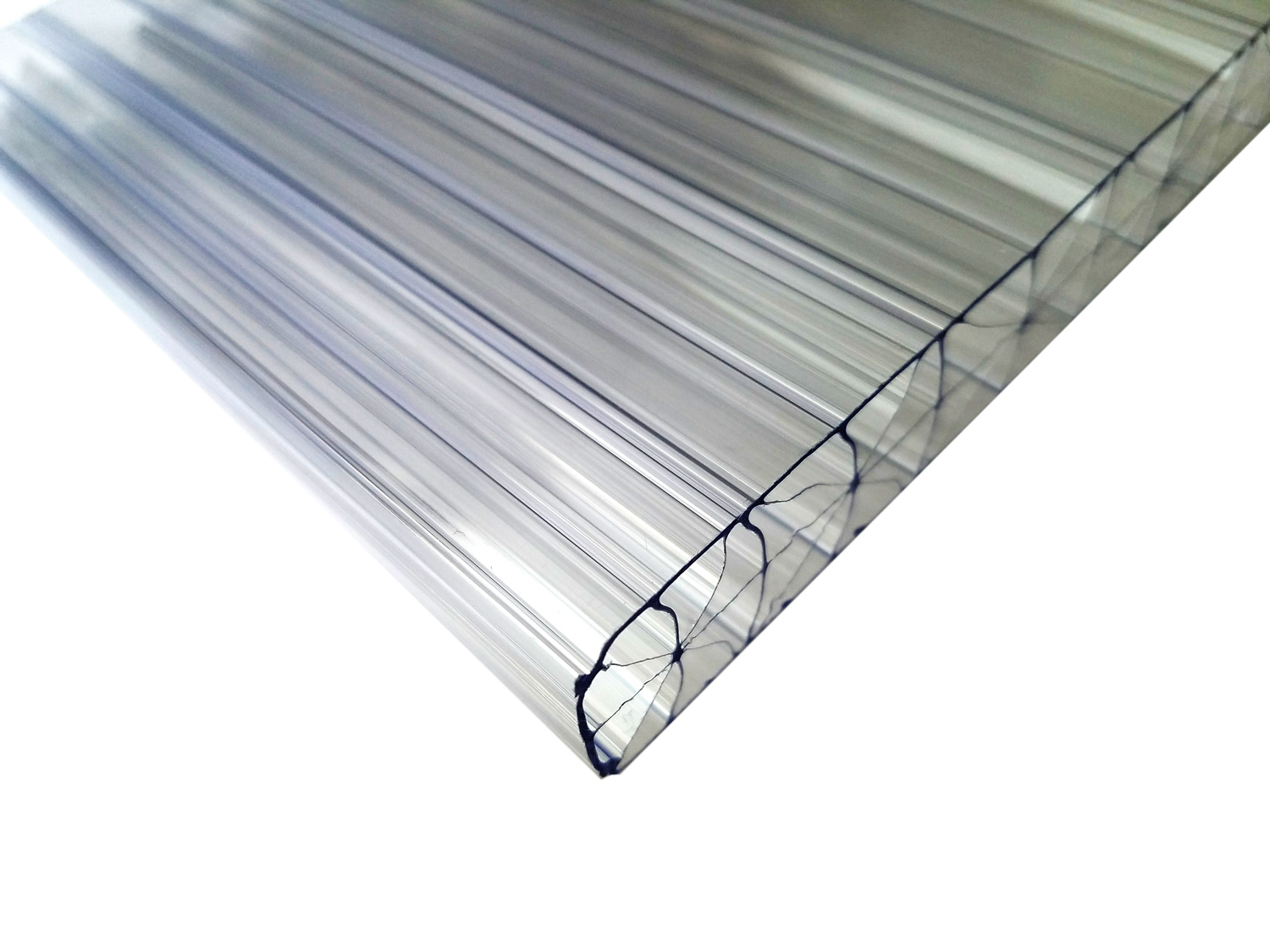

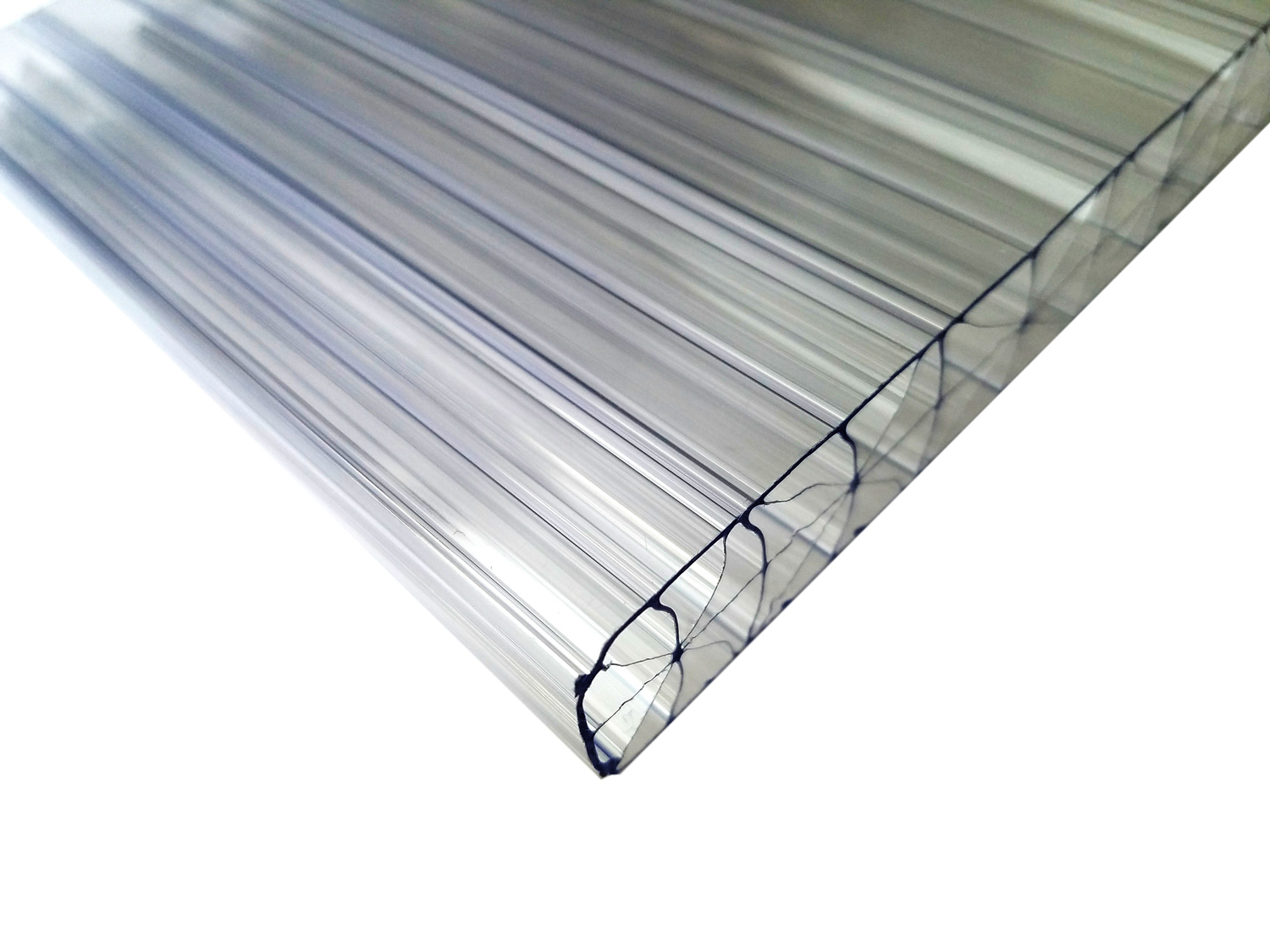

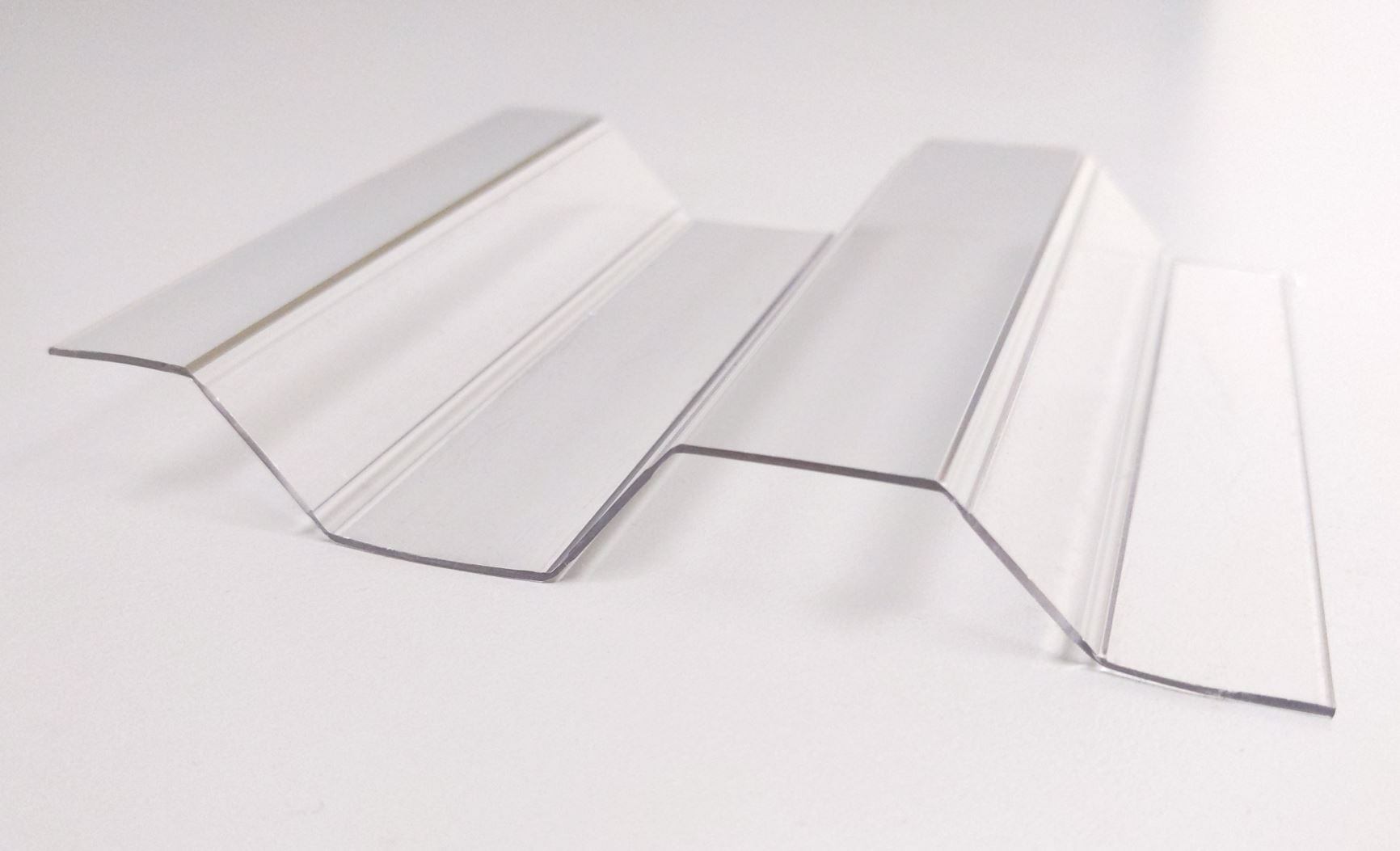

Corrugated polycarbonate with the highest Daily Light Integral and guaranteed condensate control.

Endless applications for architectural design, roofing, glazing, windows and installations.

Endless applications for architectural design, roofing, glazing, windows and installations.

Endless applications for architectural design, roofing, glazing, windows and installations.

RDC storm panels pass the Dade County Hurricane test, displaying their extreme impact resistance.

16mm RDC Storm Panels for commercial businesses and homes protect windows from strong winds and flying debris during hurricane season.

Allows light in while protecting your windows and doors from hurricane force winds, flying debris, and severe weather.

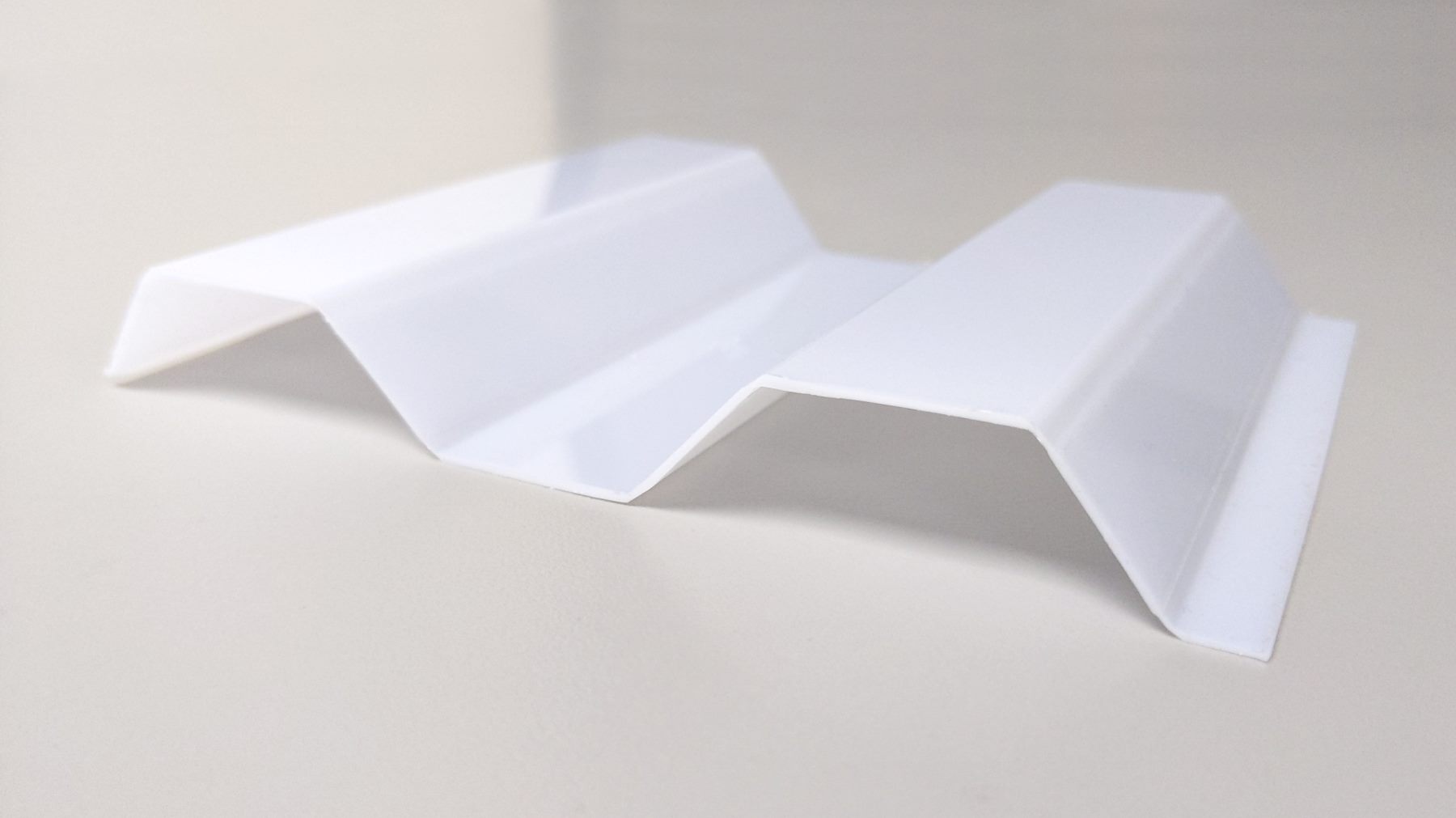

Rigid and lightweight corrugated polycarbonate panels for greenhouses and outdoor applications.

Rigid and lightweight corrugated polycarbonate panels for greenhouses and outdoor applications.

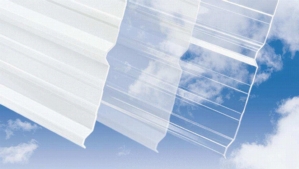

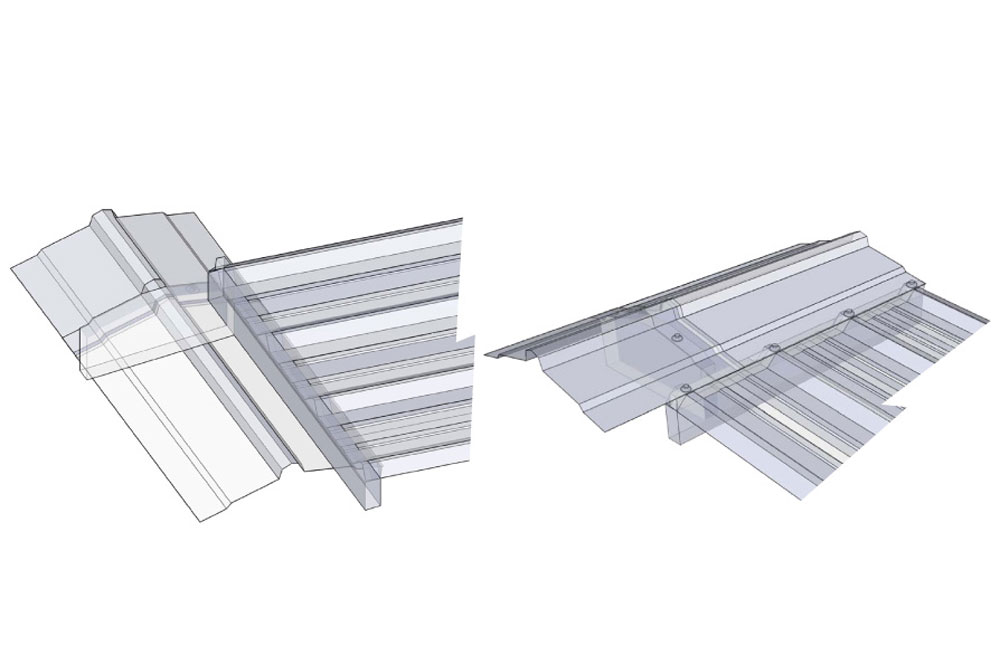

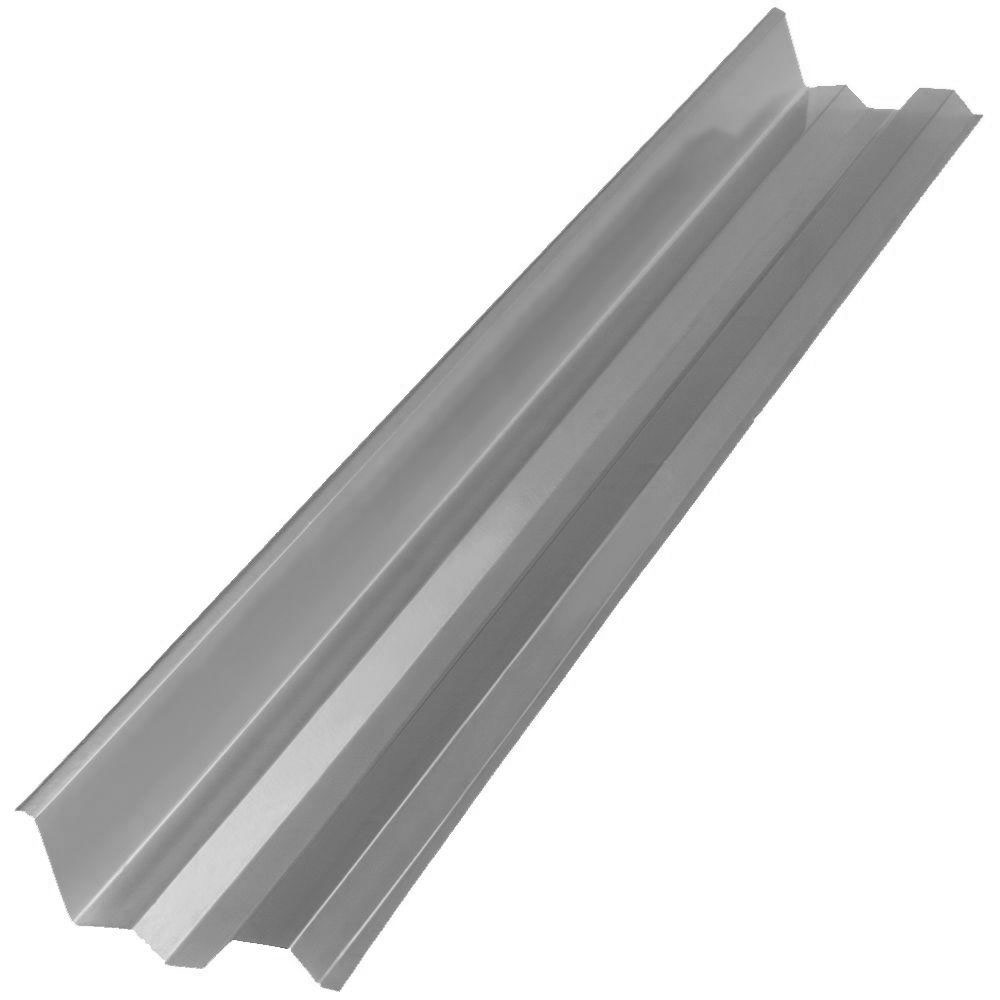

SunSky corrugated polycarbonate rooflite and sidelite panels turn night into brilliant daylight.

SunSky corrugated polycarbonate rooflite and sidelite panels turn night into brilliant daylight.

SunSky corrugated polycarbonate rooflite and sidelite panels turn night into brilliant daylight.

SunSky corrugated polycarbonate rooflite and sidelite panels turn night into brilliant daylight.

SunSky corrugated polycarbonate rooflite and sidelite panels turn night into brilliant daylight.

SunSky corrugated polycarbonate rooflite and sidelite panels turn night into brilliant daylight.

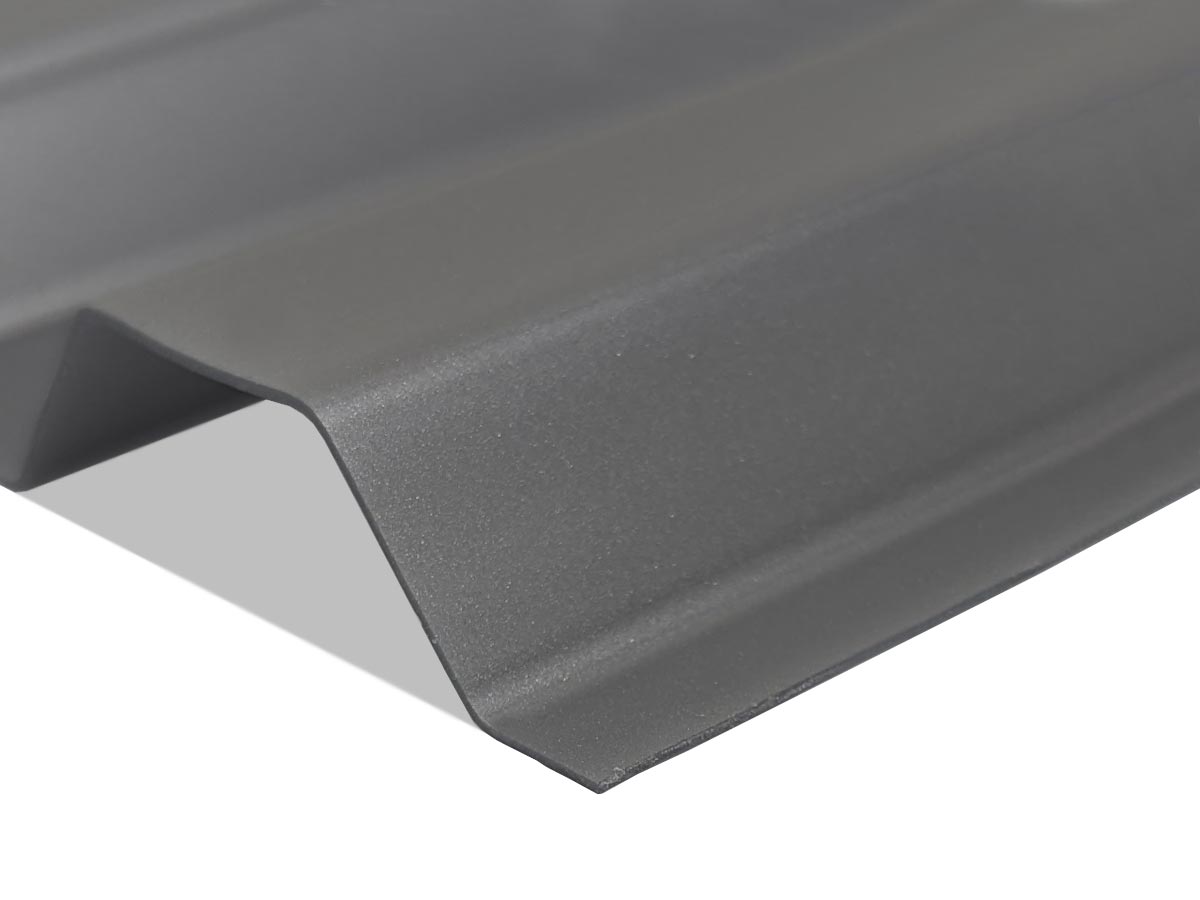

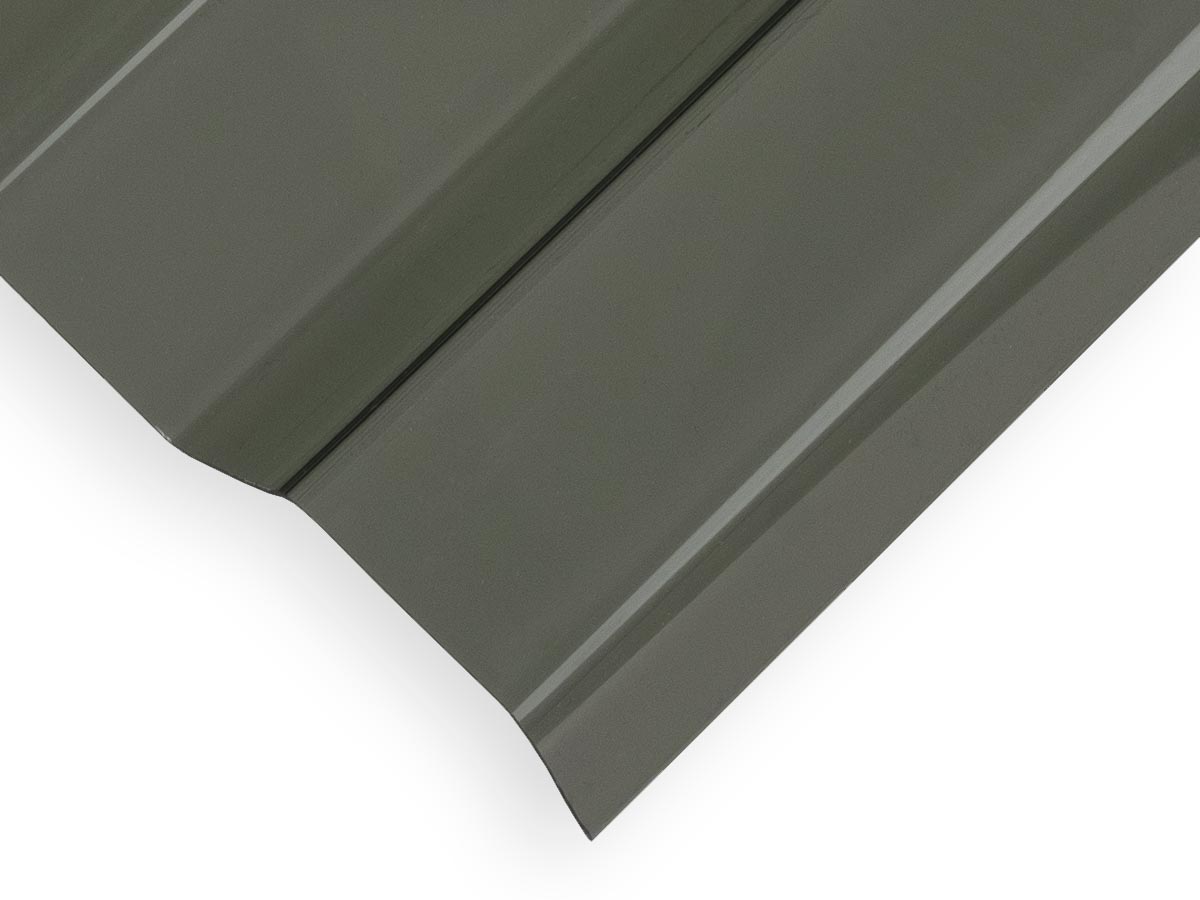

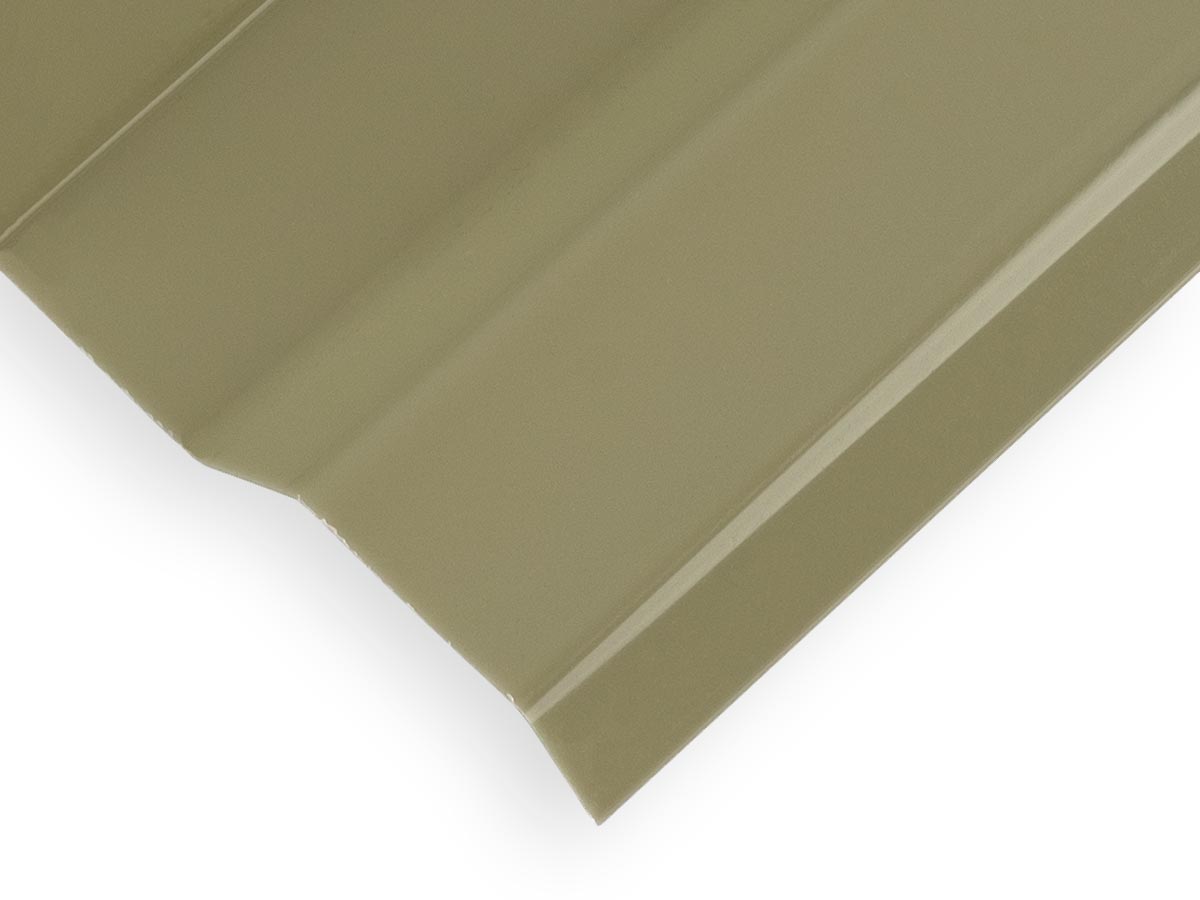

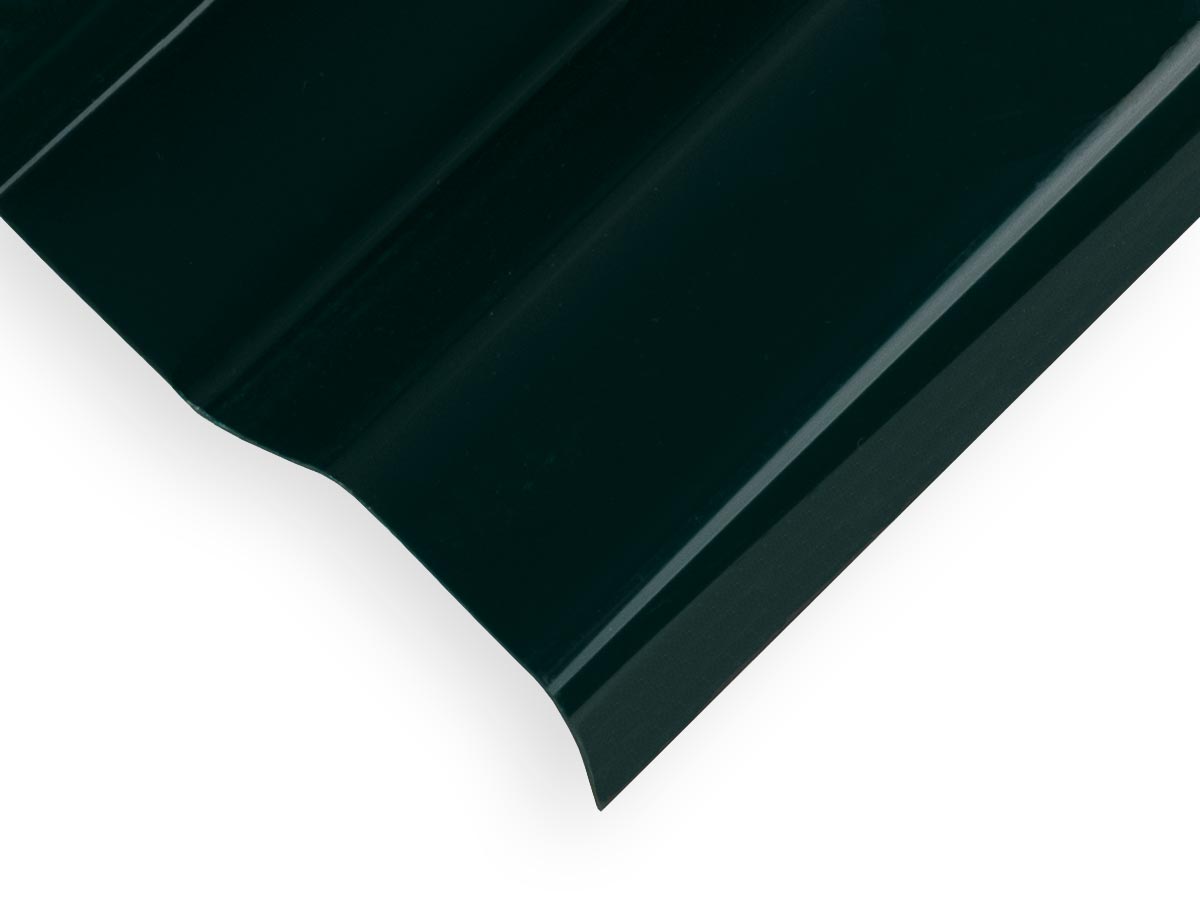

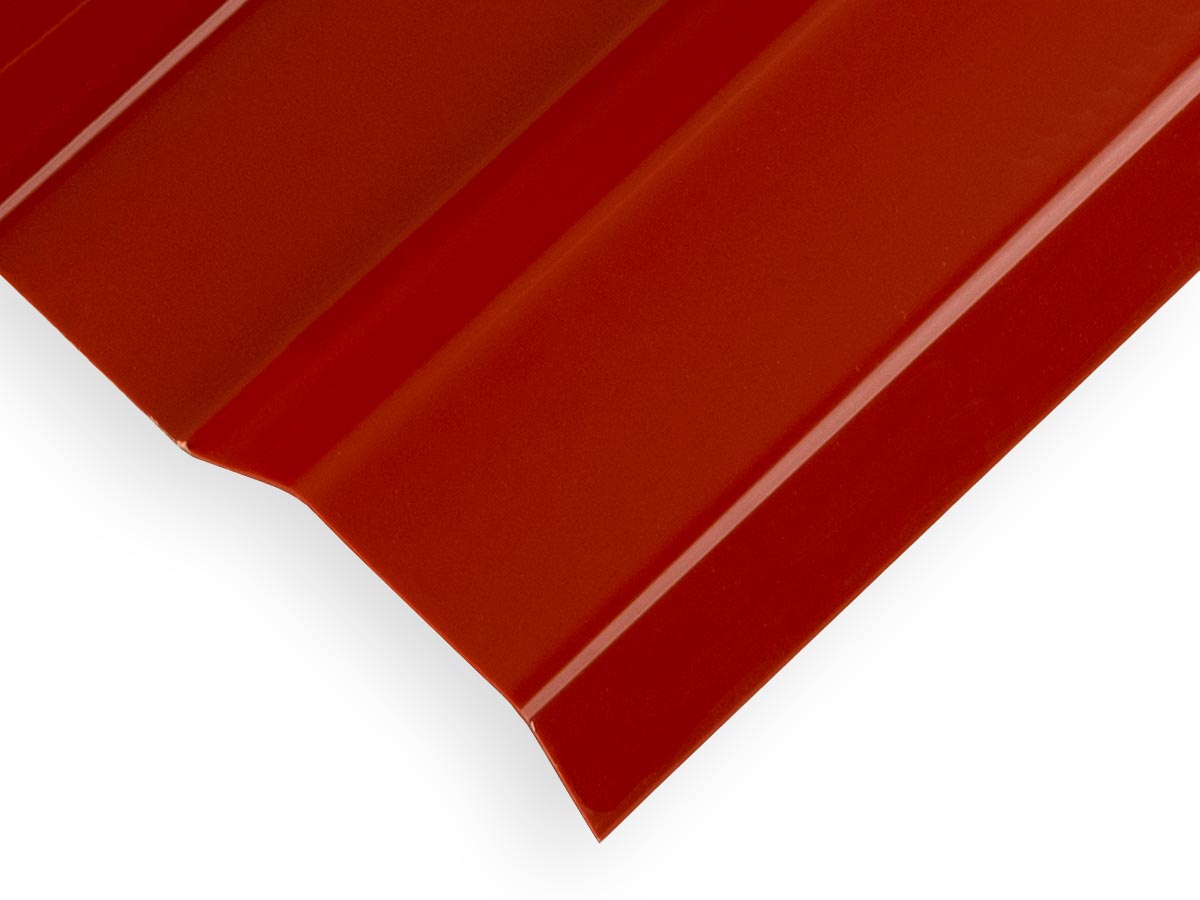

High performance glazing panels for punishing exterior applications.

High performance glazing panels for punishing exterior applications.

High performance glazing panels for punishing exterior applications.

High performance glazing panels for punishing exterior applications.

High performance glazing panels for punishing exterior applications.

High performance glazing panels for punishing exterior applications.

High performance glazing panels for punishing exterior applications.

High performance glazing panels for punishing exterior applications.

High impact strength, dimensional stability, and the lowest internal stress and inclusion levels.

Polycarbonate is a versatile, tough, durable plastic used for a variety of applications.

Aluminum vent tape for polycarbonate multi-wall applications.

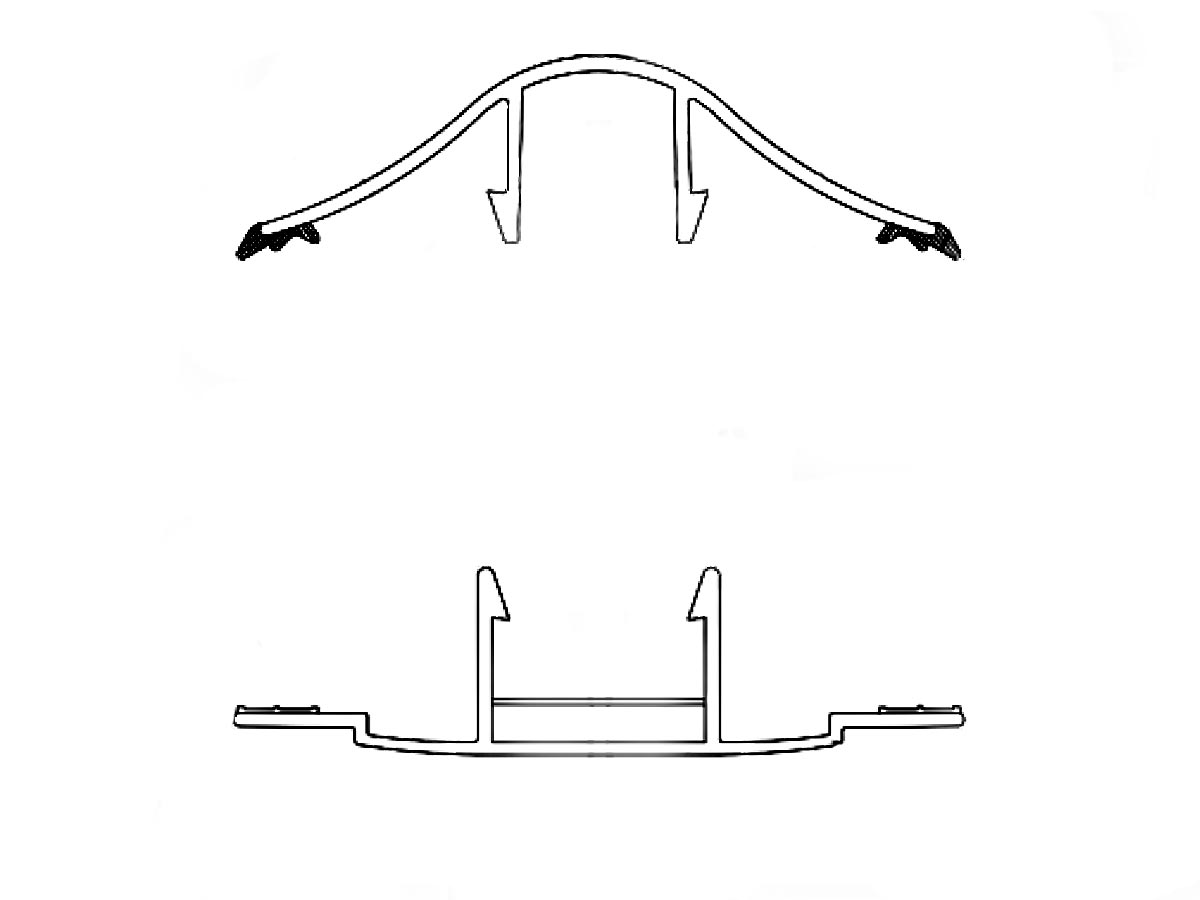

Ridge cap profiles for SunSky 9 and Sunsky 12 in clear, soft white, and white opal.

Ridge cap profiles for SunTuf polycarbonate.

Side ridge profiles for SunTuf polycarbonate.

Wall connector profiles for SunTuf polycarbonate.

Pack of six SunTuf horizontal 2ft plastic closure strips for SunTuf corrugated panels.

Pack of six SunTuf horizontal 2ft wooden closure strips for SunTuf corrugated panels.

Pack of five universal 2ft plastic closure strips for SunTuf and other corrugated panels.

Pack of five universal 2ft wooden closure strips for SunTuf and other corrugated panels.

36 inch SunTuf horizontal foam closure strips for SunTuf corrugated panels.

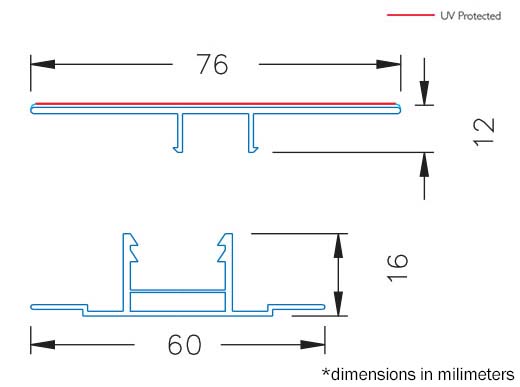

For use with .630" (16mm) Polycarbonate Twinwall.

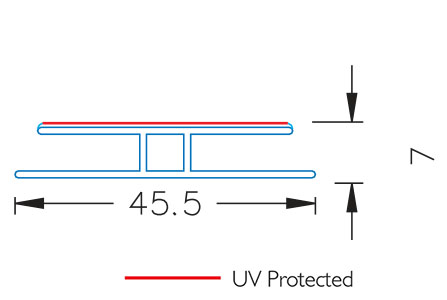

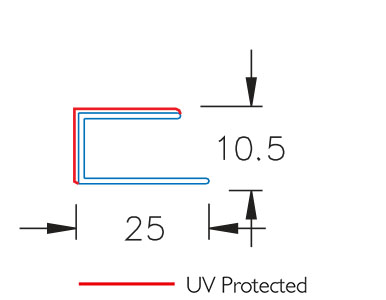

For use with .236" (6mm) Polycarbonate Twinwall.

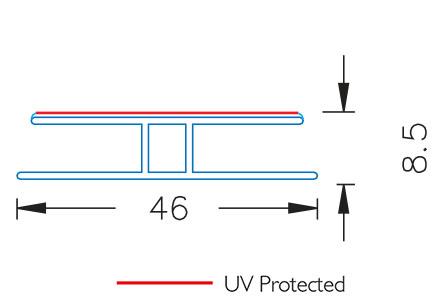

For use with .315" (8mm) Polycarbonate Twinwall.

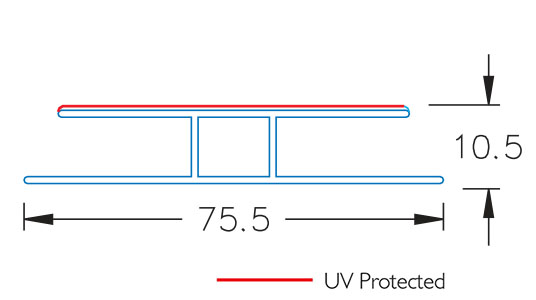

For use with .394" (10mm) Polycarbonate Twinwall.

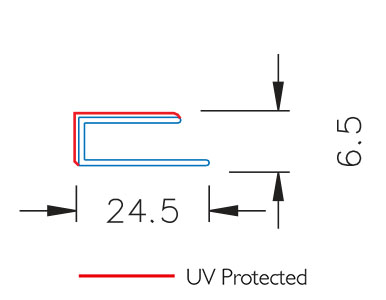

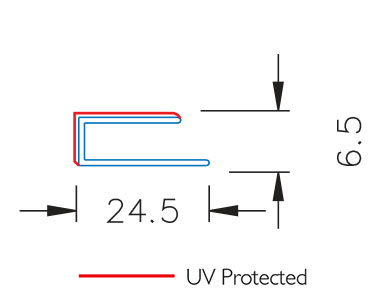

For use with .236" (6mm) Polycarbonate Twinwall.

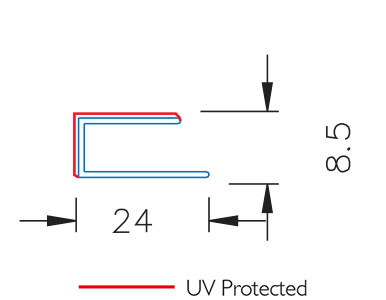

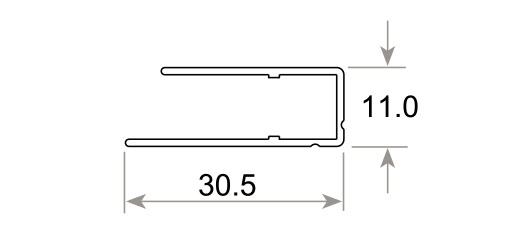

For use with .315" (8mm) Polycarbonate Twinwall.

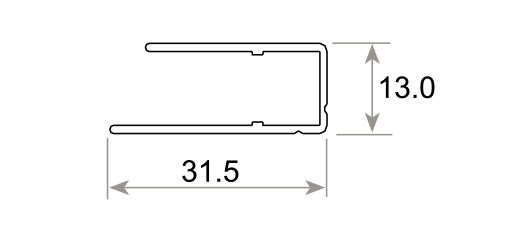

For use with .394" (10mm) Polycarbonate Twinwall.

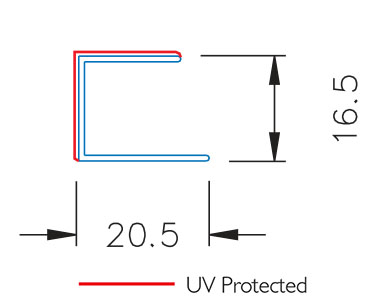

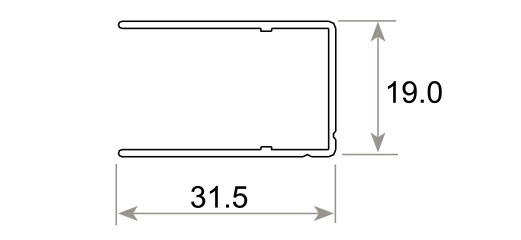

For use with .630" (16mm) Polycarbonate Twinwall.

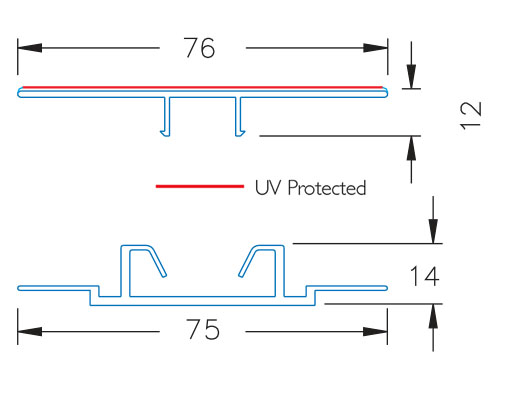

For use with .236" (6mm), .315" (8mm), and .394" (10mm) Polycarbonate Twinwall.

For use with .630" (16mm) Polycarbonate Twinwall.

For use with .630" (16mm) Polycarbonate Twinwall.

(Part #311) For use with .315" (8mm) Polycarbonate Twinwall.

(Part #312) For use with .394" (10mm) Polycarbonate Twinwall.

(Part #313) For use with .630" (16mm) Polycarbonate Twinwall.

(Part #400) Point-fastening 2 in. hex screw with bubble washer.

(Part #422) Point-fastening 6-16 mm. screw with bubble washer.

(Part #450) Supports base-to-metal structures.

(Part #462) 5/8” Length

(Part #421) Supports ECP/HCP/GCP profile with a base-to-wood structure.

(Part #412) Supports HCP profile with a base-to-metal structure.

(Part #505)

(Part #473)

(Part #463) 7/8” Length

Metal screws for attaching corrugated polycarbonate to metal framing.

Metal screws for attaching corrugated polycarbonate to metal framing.

Wood screws for attaching corrugated polycarbonate to wood & other wood fastening applications.

Wood screws for attaching corrugated polycarbonate to wood & other wood fastening applications.

1 Inch aluminum washer with included gasket. Quantity 100 per box. (Part #472)

WARNING: The products on this page can expose you to chemicals including Bisphenol A, CAS 80-05-7, which are known to the State of California to cause birth defects or other reproductive harm. For more information go to www.p65warnings.ca.gov.