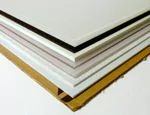

Renovo-HIPS 25% post-consumer recycled styrene sheet has the same properties as virgin styrene.

High impact styrene is used for models, prototypes, signs, displays, enclosures, and more.

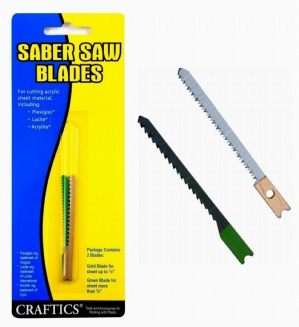

This material can be cut with a utility knife and glued together using fast acting solvent adhesive.

Multi-Pack Sheets of .060x12x12" High-Impact White Styrene Sheets.

12 x 12" samples of thermoforming naterials.

Plastic cutting bits by Onsrud are an industry standard in quality.

Plastic cutting bits by Onsrud are an industry standard in quality.

Lightweight standalone hot knife thermocutter with T3/30 blade.

Designed to cut styrene so smoothly that edges can be polished.

WARNING: The products on this page can expose you to chemicals including 1,3-Butadiene, CAS 106-99-0, which are known to the State of California to cause cancer. For more information go to www.p65warnings.ca.gov.

WARNING: The products on this page can expose you to chemicals including Styrene, CAS 100-42-5, which are known to the State of California to cause birth defects or other reproductive harm. For more information go to www.p65warnings.ca.gov.