The ultimate choice for high service temperature, flame retardant plastic sheet.

Halar ECTFE has become the material of choice for several applications in corrosion protection.

Halar ECTFE 902 sheet is commonly used in semiconductor applications and is great for corrosion protection.

Flame resistant material for semiconductor clean rooms and electrical equipment.

High melting point fluorinated thermoplastic copolymer sheet.

A high performance, fire retardant material for the semiconductor industry.

An enhanced PVC Type 1 sheet formulated for exceptional fire retardant properties.

Class A fire rated USDA, FDA, and LA County compliant decorative panels for walls and ceilings.

Clear fire resistant sheet for clean room glazing applications.

UL94 V-0 compliance, durability, strength, and chemical resistance at cost-effective price.

Low flammability homopolymeric polyvinylidene fluoride.

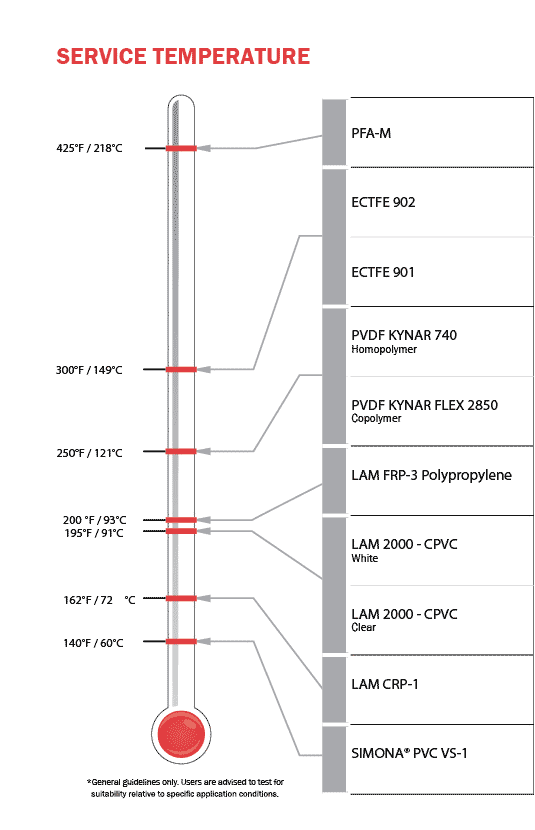

CPVC is a durable material with higher heat resistance & more flexibility compared to standard PVC.

Simona CRP-1 FM4910 rated PVC coiled welding rod has increased impact & temperature resistance.

Flame resistant PVDF rod for welding in semicon clean rooms & electrical equipment applications.

WARNING: The products on this page can expose you to chemicals including Polyvinyl Chloride, CAS 9002-86-2, which are known to the State of California to cause cancer. For more information go to www.p65warnings.ca.gov.

WARNING: The products on this page can expose you to chemicals including Tetrafluoroethylene, CAS 116-14-3, which are known to the State of California to cause cancer. For more information go to www.p65warnings.ca.gov.

WARNING: The products on this page can expose you to chemicals including Tetrafluoroethylene, CAS 116-14-3, which are known to the State of California to cause birth defects or other reproductive harm. For more information go to www.p65warnings.ca.gov.