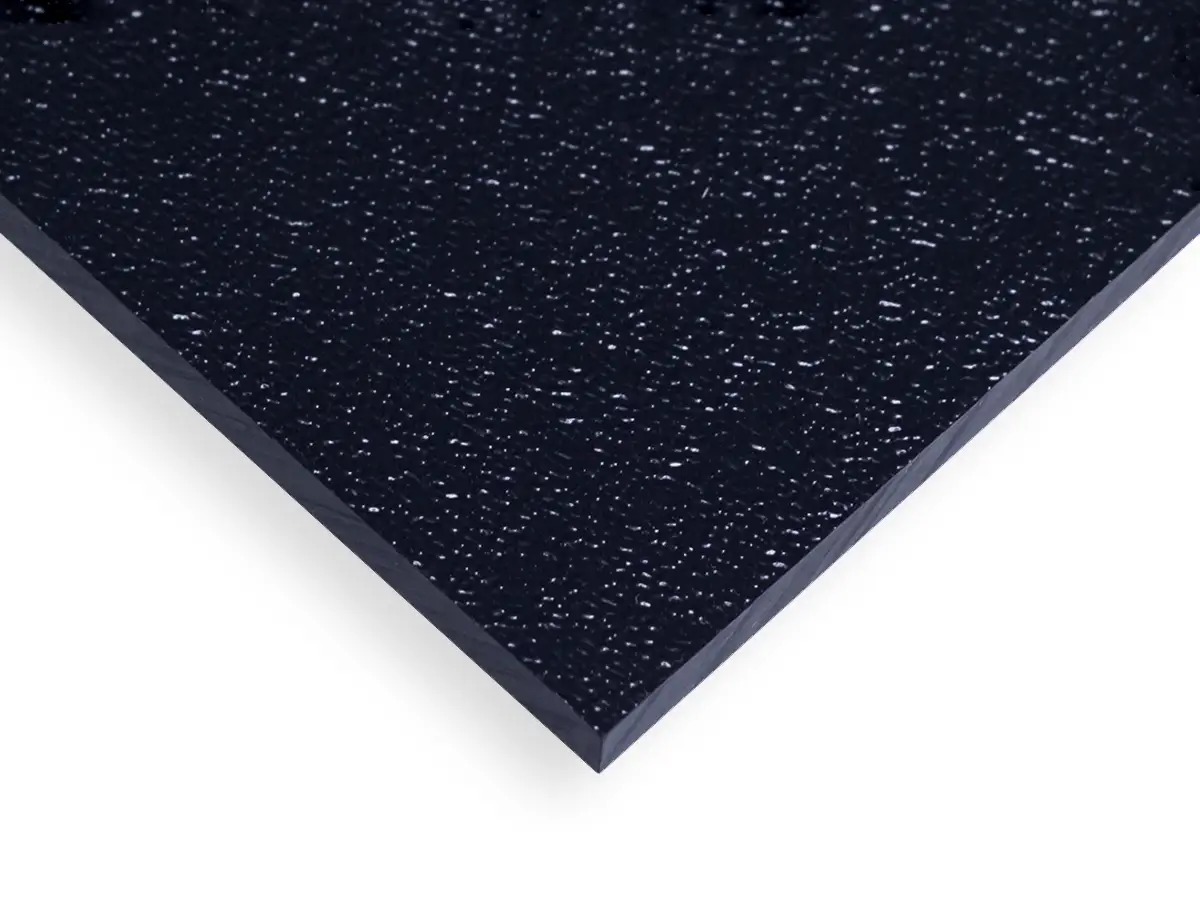

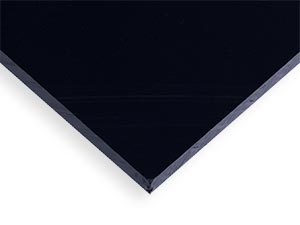

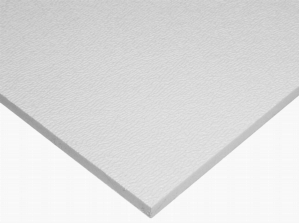

ABS plastic is an easily machined, low cost, rigid thermoplastic plastic with high impact strength.

ABS plastic is an easily machined, low cost, rigid thermoplastic plastic with high impact strength.

ABS plastic is an easily machined, low cost, rigid thermoplastic plastic with high impact strength.

ABS plastic is an easily machined, low cost, rigid thermoplastic plastic with high impact strength.

ABS plastic is an easily machined, low cost, rigid thermoplastic plastic with high impact strength.

ABS plastic is an easily machined, low cost, rigid thermoplastic plastic with high impact strength.

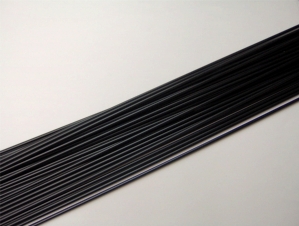

ABS welding rod is sold by the pound, shipped in 4' straight lengths.

ABS welding rod is sold by the pound, shipped in 4' straight lengths.

ABS welding rod is sold by the pound, shipped in 4' straight lengths.

Includes a 6x6" sample of ABS, Noryl, Polycarbonate, and UHMW.

6x6" sample of ABS, Acetal, Acrylic, Nylon, PVC, UHMW, PET, and a 3x3" sample of PTFE.

6x6" sample of ABS, Acetal, Acrylic, HDPE, PVC, UHMW, and 3x3" sample of PTFE.

Plastic cutting bits by Onsrud are an industry standard in quality.

Plastic cutting bits by Onsrud are an industry standard in quality.

24" 55-Watt Plastrip Heater.

Applicator for applying solvent cements to acrylics and other plastics.

Universal 2oz applicator and funnels for applying solvent cements to acrylics and other plastics.

10 funnels for filling small bottles and syringes.

Saw blades that offer premium performance on hard and soft plastics.

WARNING: The products on this page can expose you to chemicals including Acrylonitrile, CAS 107-13-1, which are known to the State of California to cause cancer. For more information go to www.p65warnings.ca.gov.

WARNING: The products on this page can expose you to chemicals including Styrene, CAS 100-42-5, which are known to the State of California to cause birth defects or other reproductive harm. For more information go to www.p65warnings.ca.gov.