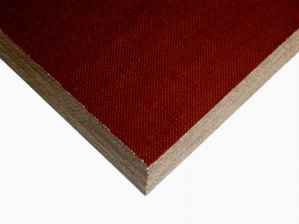

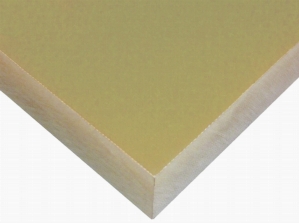

"C" Grade Natural Canvas Phenolic Sheet.

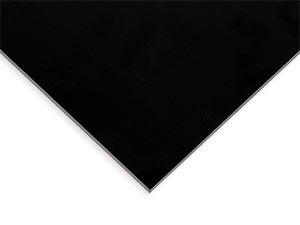

Of the phenolic sheet grades, CE grade phenolic sheet is considered 'electrical' grade.

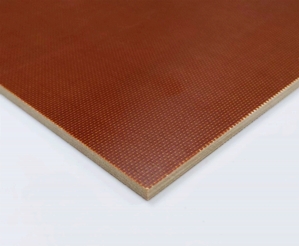

Natural LE Phenolic Sheet.

Economy Natural Paper Phenolic Sheet.

XX grade paper phenolic is used in mechanical and electrical applications.

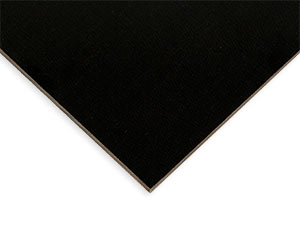

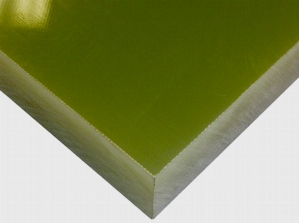

Woven glass fabric high temperature phenolic sheet with excellent mechanical properties.

G-7 grade phenolic sheet is unparalleled for arc resistant or high heat applications.

G-9 phenolic sheet has good mechanical properties & high resistance to flames, heat, & alkali solutions.

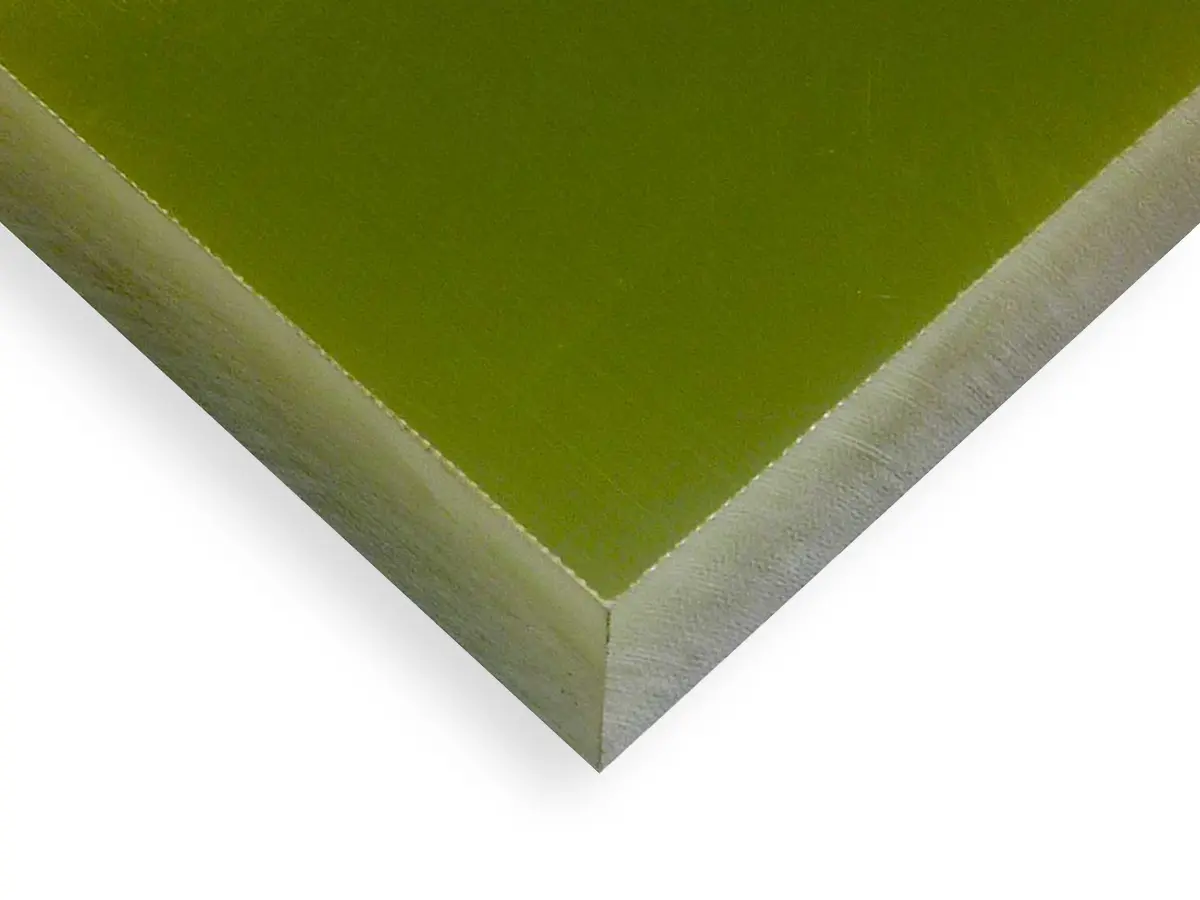

G10 phenolic sheet is a non-flame retardant glass epoxy composite sheet.

Suitable for a variety of structural, high humidity, and electrical insulation applications.

Suitable for a variety of structural, high humidity, and electrical insulation applications.

Similar composition to G-10. G-11 phenolic is used at higher temperatures that G-10 cannot handle.

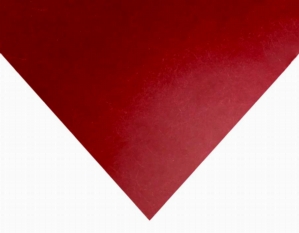

Excellent track, arc, and flame resistance.

NorPLY™ 1002 vibratory or shaker springs are ideal for fatigue-intensive applications.

NorPLY™ 1002 epoxy composite is used to make components for fatigue-intensive applications.

NorPLY™ 1002 uses non-woven parallel filaments to reduce filament stress & increase its fatigue life.

Wear & impact resistant pile cushion hammer pads for pile driving applications.

CE grade phenolic rod is considered 'electrical' grade.

LE phenolic rods have excellent electrical properties that regular linen phenolic rods do not.

G-7 grade phenolic is preferred for applications where arc or high heat resistance is necessary.

G-9 grade phenolic has good mechanical properties & high resistance to heat & alkali solutions.

G10 FR4 glass epoxy rods suitable for structural, high humidity, and electrical insulation applications.

G-11 phenolic rod is a high heat plastic suitable for continuous use at elevated temperatures.

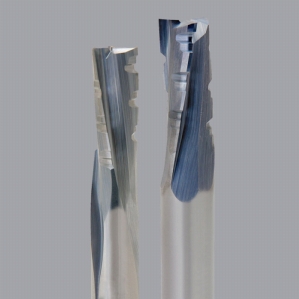

Router bits designed to route phenolic with greater feed rates and reduced lateral tool stress.

Plastic cutting bits by Onsrud are an industry standard in quality.

Plastic cutting bits by Onsrud are an industry standard in quality.

Saw blades that offer premium performance on hard and soft plastics.