Acetal is a tough, stable engineering thermoplastic.

Acetal is a tough, stable engineering thermoplastic.

Delrin offers an excellent balance of properties that bridge the gap between metals and plastic.

Delrin vs Acetal - Delrin sheets and Delrin plastic offer an excellent balance of properties.

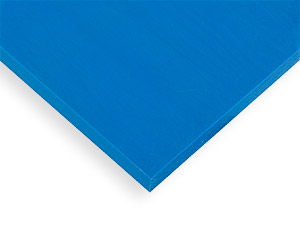

A blue FDA compliant copolymer acetal sheet.

ESD Acetal contains no carbon fibers or powders and is for clean room use.

Acetal AF blend has excellent sliding/friction/wear properties.

Ultra detectable acetal copolymer plate designed for food contact applications.

Acetal is a tough, stable engineering thermoplastic.

Acetal is a tough, stable engineering thermoplastic.

Acetal homopolymer (Delrin) has more mechanical strength and stiffness than acetal copolymer.

Acetal homopolymer (Delrin) has more mechanical strength and stiffness than acetal copolymer.

Delrin 527UV rods are UV stabilized for enhanced protection against ultraviolet rays.

Acetal is a tough, stable engineering thermoplastic.

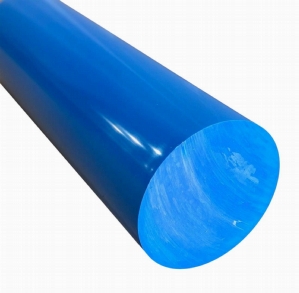

A blue FDA compliant copolymer acetal rod.

Ultra detectable acetal copolymer rod designed for food contact applications.

Acetal copolymer tubes have low moisture absorption and high strength, stiffness, and stability.

Turcite A is a self-lubricating engineered thermoplastic.

Turcite X is a self-lubricating engineered thermoplastic.

Includes a 6x6" sample of Acetal, Nylon, UHMW, and a 3x3" sample of PTFE.

6x6" sample of ABS, Acetal, Acrylic, HDPE, PVC, UHMW, and 3x3" sample of PTFE.

6x6" sample of ABS, Acetal, Acrylic, Nylon, PVC, UHMW, PET, and a 3x3" sample of PTFE.

Includes 3x3" samples of PEEK, PTFE, and Ultem (PEI).

Plastic cutting bits by Onsrud are an industry standard in quality.

Plastic cutting bits by Onsrud are an industry standard in quality.

Saw blades that offer premium performance on hard and soft plastics.

WARNING: The products on this page can expose you to chemicals including Formaldehyde, CAS 50-00-0, which are known to the State of California to cause cancer. For more information go to www.p65warnings.ca.gov.

WARNING: The products on this page can expose you to chemicals including Hexachlorobenzene, CAS 118-74-1, which are known to the State of California to cause birth defects or other reproductive harm. For more information go to www.p65warnings.ca.gov.