Nylon has a combination of toughness, dimensional stability, wear resistance, and versatility.

Nylon has a combination of toughness, dimensional stability, wear resistance, and versatility.

Nylatron® NSM was developed for demanding applications where larger size parts are required.

Nylon MD has a low coefficient of friction, good wear resistance, toughness, & light weight.

Nylatron® NSM was developed for demanding applications where larger size parts are required.

Nylatron® GSM PA6 should be considered for any oil-filled Nylon application.

Nylatron® 703XL PA6 provides an extraordinary amount of control for high precision applications.

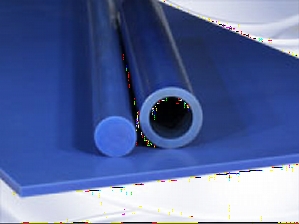

Nylatron® MC901 blue nylon should be considered for wheels, gears, and custom parts.

Cast nylon XHA is heat stabilized for use in higher temperature applications than standard nylon.

Nylon has a combination of toughness, dimensional stability, wear resistance, and versatility.

Nylon MD has a low coefficient of friction, good wear resistance, toughness, & light weight.

Hydlar Z nylon PA66 sheets are abrasion resistant plastic sheets with great wear properties.

An internally lubricated cast nylon 6 sheet with high strength and reduced friction properties.

Nylon has a combination of toughness, dimensional stability, wear resistance, and versatility.

Nylon has a combination of toughness, dimensional stability, wear resistance, and versatility.

Nyloil®-FG is a self lubricating Nylon bearing material approved for food contact.

Extruded nylon rods have a fantastic combination of stability, toughness, and wear resistance.

Nylon has a combination of toughness, dimensional stability, wear resistance, and versatility.

Nylon has a combination of toughness, dimensional stability, wear resistance, and versatility.

Nylatron® NSM was developed for demanding applications where larger size parts are required.

Nylon has a combination of toughness, dimensional stability, wear resistance, and versatility.

Glass-filled nylon is used for technical parts that require particular stiffness, high heat distortion temperature, and low abrasive wear.

Hydlar Z nylon PA66 rod is an abrasion resistant plastic with great wear properties.

Nylatron® MC901 blue nylon should be considered for wheels, gears, and custom parts.

Nylon has a combination of toughness, dimensional stability, wear resistance, and versatility.

Nylatron® GSM PA6 should be considered for any oil-filled Nylon application.

Self-lubricating cast nylon tube with improved dimensional stability over standard cast nylon.

Nylatron® GSM PA6 should be considered for any oil-filled Nylon application.

Tough, dimensionally stable extruded nylon bushing stock with good wear resistance and versatility.

Cast nylon XHA is heat stabilized for use in higher temperature applications than standard nylon.

Includes a 6x6" sample of Acetal, Nylon, and PET.

Includes a 6x6" sample of Acetal, Nylon, UHMW, and a 3x3" sample of PTFE.

6x6" sample of ABS, Acetal, Acrylic, Nylon, PVC, UHMW, PET, and a 3x3" sample of PTFE.

Standard nylon cable ties in black.

Standard nylon cable ties in white/natural color.

WARNING: The products on this page can expose you to chemicals including N,N-Dimethylformamide, CAS 68-12-2, which are known to the State of California to cause cancer. For more information go to www.p65warnings.ca.gov.

WARNING: The products on this page can expose you to chemicals including METHYLPYRROLIDONE, CAS 872-50-4, which are known to the State of California to cause birth defects or other reproductive harm. For more information go to www.p65warnings.ca.gov.