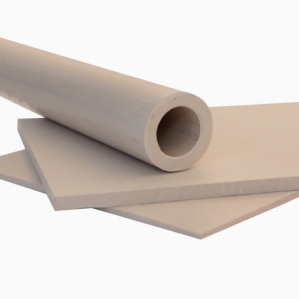

PTFE offers exceptional resistance to high temperatures, chemicals, corrosion and stress cracking.

PTFE offers exceptional resistance to high temperatures, chemicals, corrosion and stress cracking.

Halar ECTFE has become the material of choice for several applications in corrosion protection. ECTFE has similar properties to PTFE.

Halar ECTFE has become the material of choice for several applications in corrosion protection. ECTFE has similar properties to PTFE.

Fluorosint® offers an excellent combo of low frictional properties and stability.

Fluorosint® offers an excellent combo of low frictional properties and stability.

PTFE film for industrial applications resists high temperatures & has great electrical properties.

PTFE has extreme heat and chemical resistance, with an extremely low friction coefficient.

PTFE has extreme heat and chemical resistance, with an extremely low friction coefficient.

PTFE has extreme heat and chemical resistance, with an extremely low friction coefficient.

Fluorosint® offers an excellent combo of low frictional properties and stability.

Fluorosint® offers an excellent combo of low frictional properties and stability.

PCTFE features high compressive strength and stability over a wide range of temperatures.

Extruded PTFE tubes withstand high heat temperatures, corrosion, and harsh chemicals.

Includes 3x3" samples of PEEK, PTFE, and Ultem (PEI).

Includes a 6x6" sample of Acetal, Nylon, UHMW, and a 3x3" sample of PTFE.

6x6" sample of ABS, Acetal, Acrylic, HDPE, PVC, UHMW, and 3x3" sample of PTFE.

6x6" sample of ABS, Acetal, Acrylic, Nylon, PVC, UHMW, PET, and a 3x3" sample of PTFE.

Plastic cutting bits by Onsrud are an industry standard in quality.

Plastic cutting bits by Onsrud are an industry standard in quality.

Saw blades that offer premium performance on hard and soft plastics.

WARNING: The products on this page can expose you to chemicals including Tetrafluoroethylene, CAS 116-14-3, which are known to the State of California to cause cancer. For more information go to www.p65warnings.ca.gov.

WARNING: The products on this page can expose you to chemicals including Tetrafluoroethylene, CAS 116-14-3, which are known to the State of California to cause birth defects or other reproductive harm. For more information go to www.p65warnings.ca.gov.