Polypropylene is a thermoplastic polymer used in a wide variety of applications.

Polypropylene is a high corrosion resistant material which exhibits excellent tensile strength.

Polypropylene is a thermoplastic polymer used in a wide variety of applications.

Polypropylene is a thermoplastic polymer used in a wide variety of applications.

White homopolymer polypropylene sheets have excellent chemical and corrosion resistance.

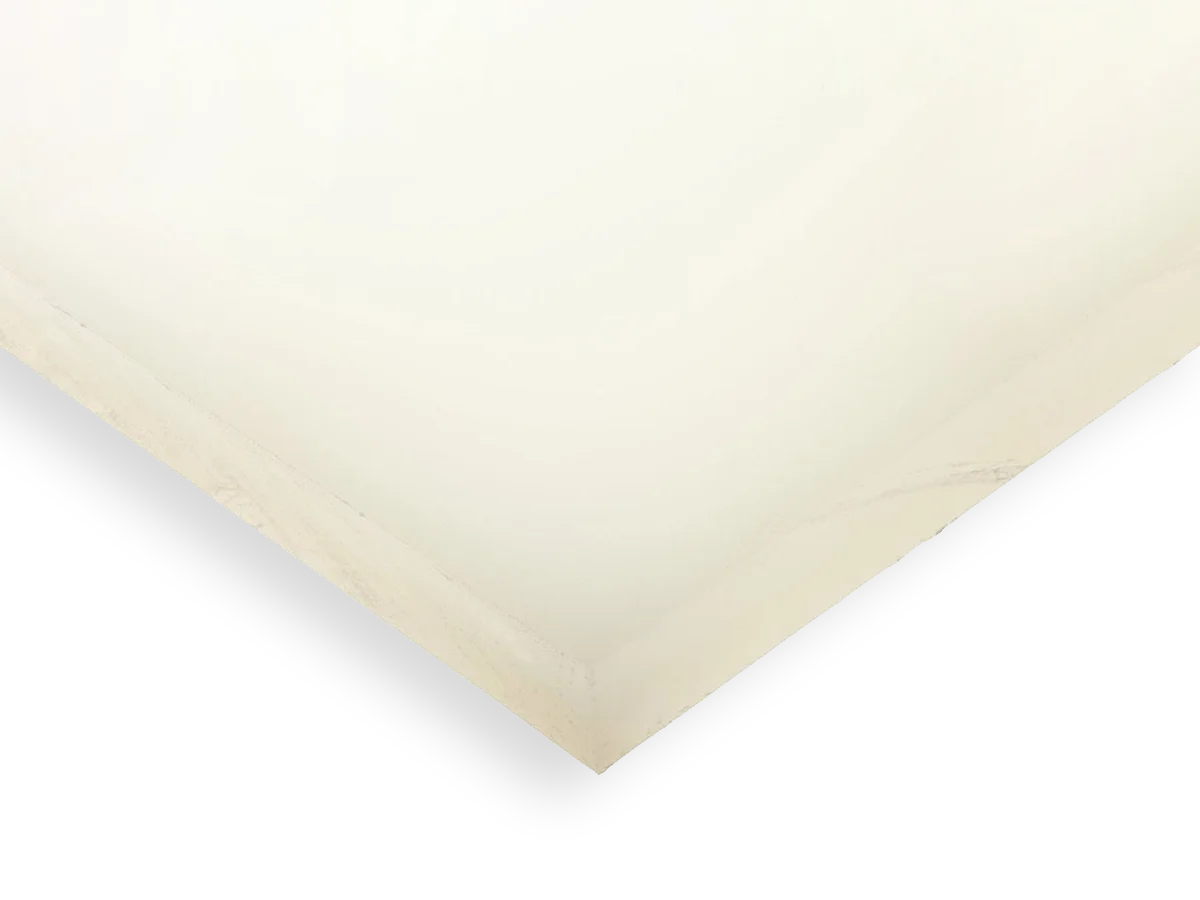

Orthotic & prosthetic grade polypropylene has outstanding rigidity and impact resistance.

Orthotic & prosthetic grade polypropylene has outstanding rigidity and impact resistance.

UL94 V-0 compliance, durability, strength, and chemical resistance at cost-effective price.

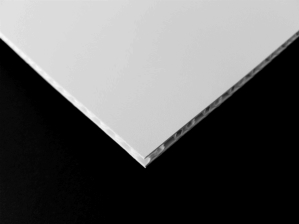

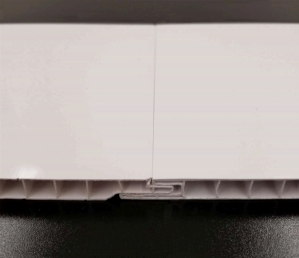

PRIME BUBBLE-X was created as an alternative to PVC because of its unique physical characteristics along with its ability to be recycled into a normal waste stream.

The need for a clean environment is met with UtiLite easy to maintain interlocking panels.

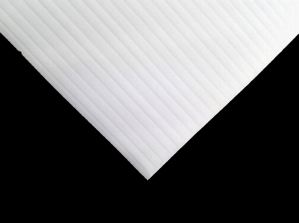

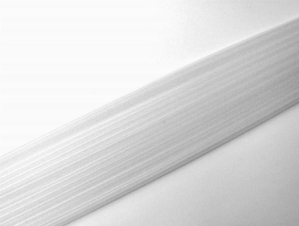

Fluted Polypro is ideal for widespread applications, most commonly for signage.

Fluted Polypro is ideal for widespread applications, most commonly for signage.

Fluted Polypro is ideal for widespread applications, most commonly for signage.

Fluted Polypro is ideal for widespread applications, most commonly for signage.

Fluted Polypro is ideal for widespread applications, most commonly for signage.

Fluted Polypro is ideal for widespread applications, most commonly for signage.

Polypropylene is a thermoplastic polymer used in a wide variety of applications.

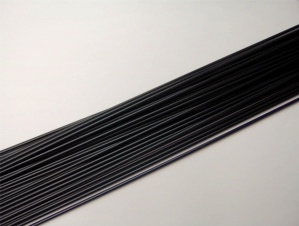

Polypropylene/polypropene (PP) welding rod is sold by the pound, shipped in 4' straight lengths.

Polypropylene/polypropene (PP) welding rod is sold by the pound, shipped in 4' straight lengths.

Polypropylene/polypropene (PP) welding rod is sold by the pound, shipped in 4' straight lengths.

Plastic cutting bits by Onsrud are an industry standard in quality.

Plastic cutting bits by Onsrud are an industry standard in quality.

Saw blades that offer premium performance on hard and soft plastics.

AZ Foremen Thermocutter Handle for GG2 Base Unit.

AZ Foremen Thermocutter Handle for GG2 Base Unit.

AZ Foremen Complete Thermocutter System.

WARNING: The products on this page can expose you to chemicals including Ethylene Oxide, CAS 75-21-8, which are known to the State of California to cause cancer. For more information go to www.p65warnings.ca.gov.

WARNING: The products on this page can expose you to chemicals including Ethylene Oxide, CAS 75-21-9, which are known to the State of California to cause birth defects or other reproductive harm. For more information go to www.p65warnings.ca.gov.