Fiberlite FRP Panels are fiberglass sheeting made for interior, moisture resistant environments and are ideal for new or retrofit construction.

Fiberlite FRP Panels are fiberglass sheeting made for interior, moisture resistant environments and are ideal for new or retrofit construction.

Fiberlite FRP Panels are fiberglass sheeting made for interior, moisture resistant environments and are ideal for new or retrofit construction.

Fiberlite FRP paneling is fiberglass reinforced plastic made for interior, moisture resistant environments. They are perfect for new or retrofit construction.

Fiberlite FRP paneling is fiberglass reinforced plastic made for interior, moisture resistant environments. They are perfect for new or retrofit construction.

Fiberlite FRP paneling is fiberglass reinforced plastic made for interior, moisture resistant environments. They are perfect for new or retrofit construction.

Fiberlite FRP paneling is fiberglass reinforced plastic made for interior, moisture resistant environments. They are perfect for new or retrofit construction.

FRP panels from Nudo are made for interior, moisture resistant environments. They are perfect for new or retrofit construction.

FRP panels from Nudo are made for interior, moisture resistant environments. They are perfect for new or retrofit construction.

FRP panels from Nudo are made for interior, moisture resistant environments. They are perfect for new or retrofit construction.

Class A fire rated USDA, FDA, and LA County compliant decorative panels for walls and ceilings.

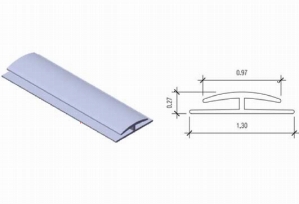

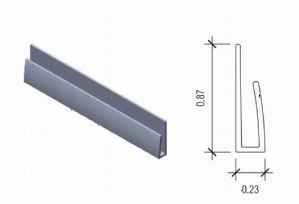

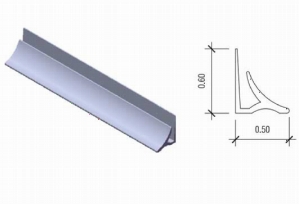

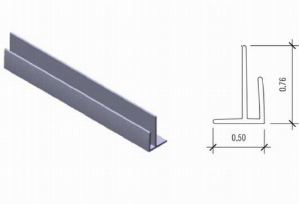

Nudo profiles are easily cut, drilled, and machined with standard tools.

Nudo profiles are easily cut, drilled, and machined with standard tools.

Nudo profiles are easily cut, drilled, and machined with standard tools.

Nudo profiles are easily cut, drilled, and machined with standard tools.