Cut-To-Size Items are Non-Returnable!

As per our Shipping and Returns Policy, custom cuts and fabricated parts are non-returnable. If you need an over- or undersized item, note it under \"Comments\" during Checkout. Cut-to-size orders have an acceptable cut tolerance of 1/8" (0.125"), so clarify if the adjustment is to be made on the (+) or (-) side of the saw blade. Please review our full return and shipping policy here.

Measure Twice, Cut OnceSince custom cuts and fabricated parts are non-refundable, be very careful while measuring your dimensions. As each cut is nominal, even the slightest miscalculation could be costly.

How to Use a Measuring TapeExtend your tape measure several inches to find the 1 and 2 inch markers. In between the inch markers you’ll find 16 equally spaced tick marks.

Measure by counting the increments beyond the nearest inch. As the increments decrease, so does the length of the mark. For example, 1/2\" has a bigger mark than 1/4\" which has a bigger mark than 1/8\". The smallest mark follows at 1/16\". Please be aware that some measuring tapes may have even smaller increments.

Features of a Measuring Tape: Sliding End HookThe sliding end hook is designed for two different types of measurements. An outside measurement (where the hook of the tape hangs over an edge), requires the hook to slide out a bit to account for the thickness of the material. When making an inside measurement (where the hook will push up against a surface), the clip slides in, again, accounting for its thickness. The measuring tape self-adjusts to guarantee an accurate measurement (as far as the tape is concerned).

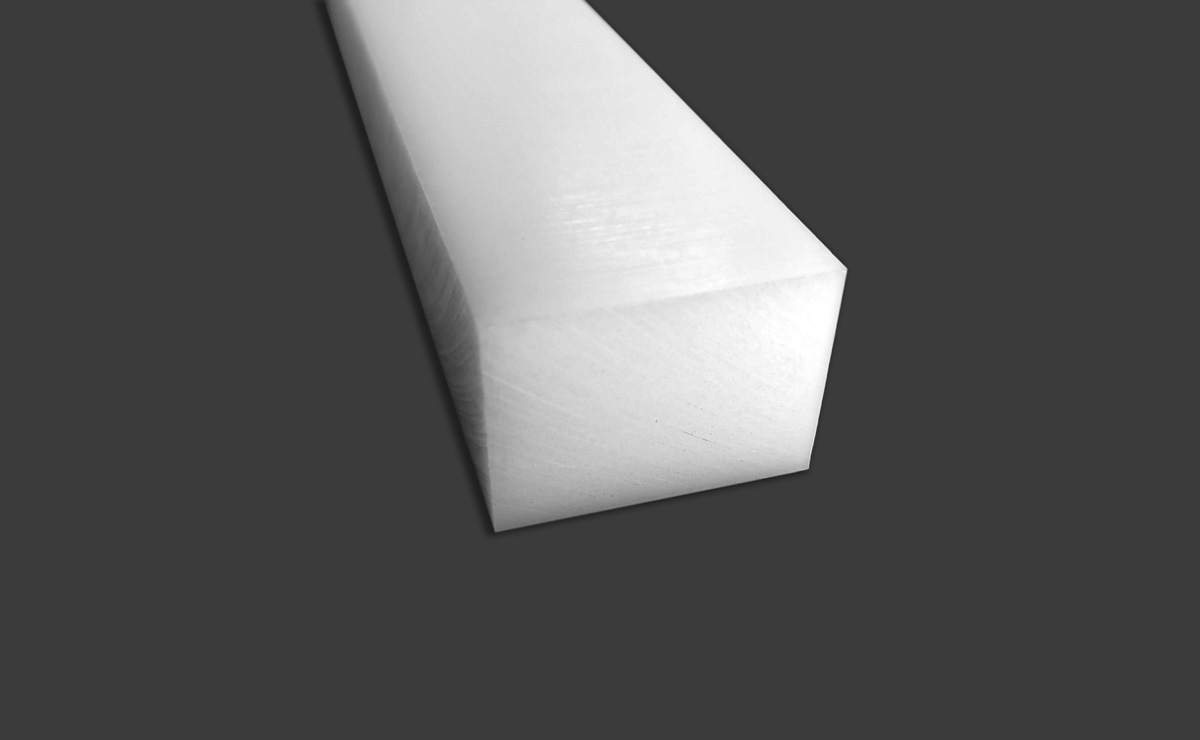

UHMW Rustication Reveal Strips

Rustication Strips For Smooth And Even Architectural Reveals.

Select your custom cut sizes:

Description

WE OFFER CUSTOM PROFILES AND STRIPS: Submit your specifications using the "Inquiry" tab on this page or use our custom quote form to send us a diagram and our representatives will provide you with a custom quote. You can also call us for more information at 888-768-5759. Rustication strips create an architectural reveal in walls or other concrete elements. Manufactured from rigid HDPE or UHMW, our rustication strips are reusable, maintain a smooth and even reveal, and are ideal for eliminating seams on form liner applications. UHMW is used for harder to release reveals, and it is a much tougher product than HDPE. HDPE is used for easy to release reveals as it is more cost-effective. Tilt-up wall construction is a widely-used method of constructing walls for buildings. In this method reveal strips and chamfer strips are used to add beauty and functionality to concrete walls by creating desired voids in a finished concrete wall or other concrete object. A tilt-up wall is typically constructed by pouring a concrete slab within forms horizontally, on the ground, then tilting up the cured concrete slab vertically to act as a wall.

- Extremely low moisture absorption

- Very low coefficient of friction

- Self-lubricating

- Highly resistant to wear and abrasion

- Easy to fabricate and machine with common shop and woodworking tools

Specifications

Specific Gravity (g/cc): 0.96

Water Absorption: 0.01% @ Saturation

Density: .93 g/cm3

Friction Coefficient: 0.2

Tensile Strength: 4600 psi

Tensile Modulus: 200 ksi

Flexural Modulus: 174 ksi

Flexural Strength: 4600 psi

Elongation: 400% @ Break / 12% @ Yield

Izod Impact Strength: 1.3 ft-lb/in.

Hardness: 70 (Shore D)

Compressive Strength: 3000 psi

Continuous Operating Temp: 180°F

Heat Deflection Temp: 116°F @ 264 psi

Melting Point: 260°F

UL94 Flammability: HB

Compliance: FDA, USDA

Dielectric Constant: 2.3

Dissipation Factor: .0005

Frequently Asked Questions

What is Interstate Advanced Materials's Shipping Policy?

Shipping will vary based on whether your order contains custom or cut-to-size products. Details about shipping can be found here.

Is Interstate Advanced Materials site secure?

Absolutely. Your information is passed through our https site when you make a purchase. Your Credit Card is never stored on file.