Endless applications for architectural design, roofing, glazing, windows and installations.

Endless applications for architectural design, roofing, glazing, windows and installations.

Endless applications for architectural design, roofing, glazing, windows and installations.

Endless applications for architectural design, roofing, glazing, windows and installations.

Endless applications for architectural design, roofing, glazing, windows and installations.

Endless applications for architectural design, roofing, glazing, windows and installations.

Endless applications for architectural design, roofing, glazing, windows and installations.

Endless applications for architectural design, roofing, glazing, windows and installations.

Endless applications for architectural design, roofing, glazing, windows and installations.

Endless applications for architectural design, roofing, glazing, windows and installations.

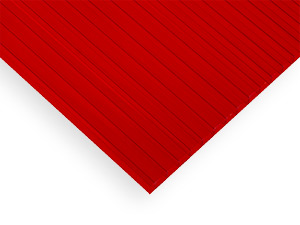

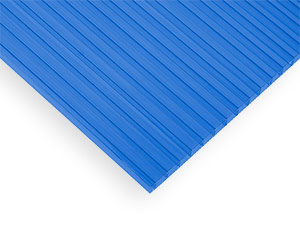

RDC storm panels pass the Dade County Hurricane test, displaying their extreme impact resistance.

16mm RDC Storm Panels for commercial businesses and homes protect windows from strong winds and flying debris during hurricane season.

Allows light in while protecting your windows and doors from hurricane force winds, flying debris, and severe weather.

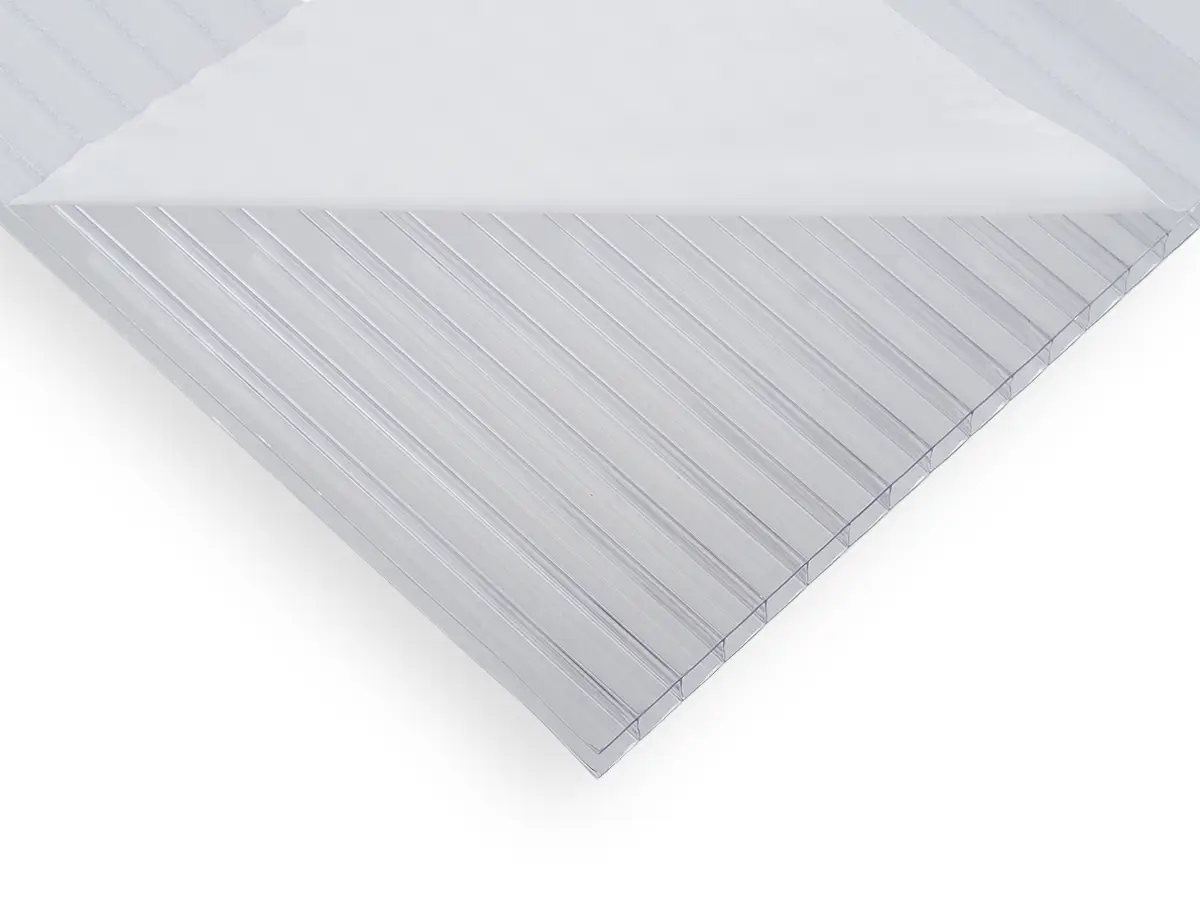

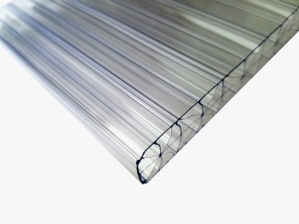

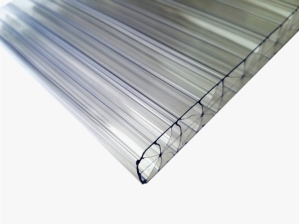

Greenhouse plastic sheet, a polycarbonate multiwall sheet, offers architectural glazing solutions.

Polycarbonate panels for greenhouses from the polycarbonate manufacturer Palram.

Polycarbonate Multiwall: Greenhouse plastic sheet from the leading polycarbonate sheet suppliers.

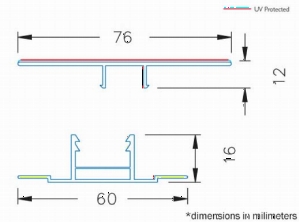

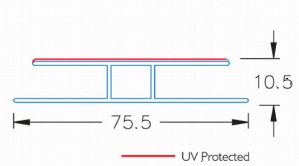

For use with .630" (16mm) Polycarbonate Twinwall

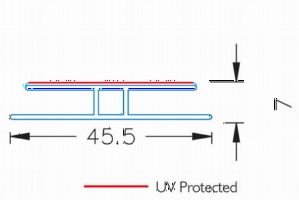

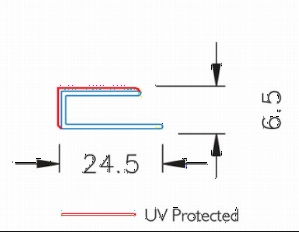

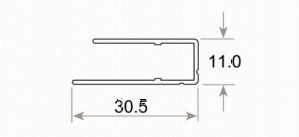

For use with .236" (6mm) Polycarbonate Twinwall

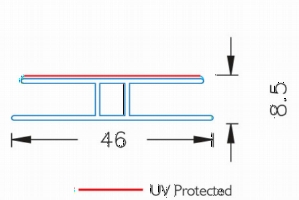

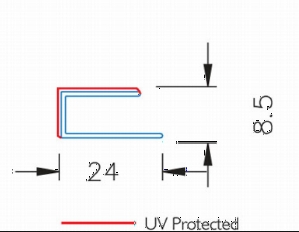

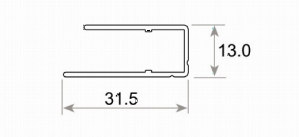

For use with .315" (8mm) Polycarbonate Twinwall

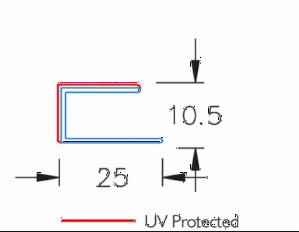

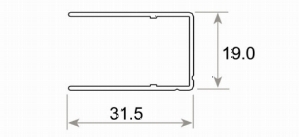

For use with .394" (10mm) Polycarbonate Twinwall

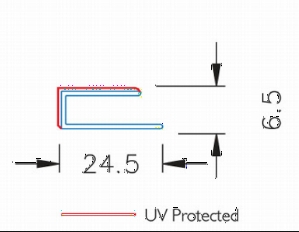

For use with .236" (6mm) Polycarbonate Twinwall

For use with .315" (8mm) Polycarbonate Twinwall

For use with .394" (10mm) Polycarbonate Twinwall

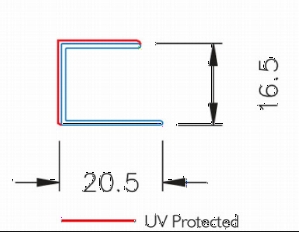

For use with .630" (16mm) Polycarbonate Twinwall

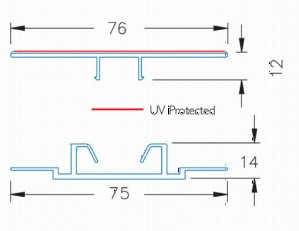

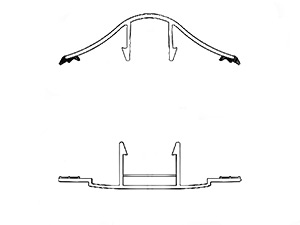

For use with .236" (6mm), .315" (8mm), and .394" (10mm) Polycarbonate Twinwall

8 mm. (#311)

10 mm. (#312)

16 mm. (#313)

Aluminum vent tape for polycarbonate multi-wall applications

(Part #400) Point-fastening 2 in. hex screw with bubble washer.

(Part #422) Point-fastening 6-16 mm. screw with bubble washer.

(Part #450) Supports base-to-metal structures.

(Part #462) 5/8” Length

(Part #421) Supports ECP/HCP/GCP profile with a base-to-wood structure.

(Part #412) Supports HCP profile with a base-to-metal structure.

(Part #505)

(Part #473)

(Part #463) 7/8” Length

(Part #472)

WARNING: The products on this page can expose you to chemicals including Bisphenol A, CAS 80-05-7, which are known to the State of California to cause birth defects or other reproductive harm. For more information go to www.p65warnings.ca.gov.