High Density Polyethylene is durable and used in many industrial applications.

HDPE cutting board is engineered for durability, low maintenance and safety.

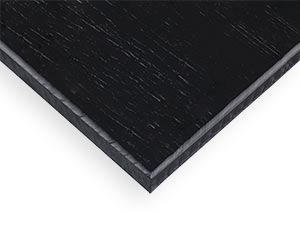

Black HDPE sheets with excellent weldability and chemical resistance.

HDPE has high impact strength and a low coefficient of friction.

Rustication strips for smooth and even architectural reveals.

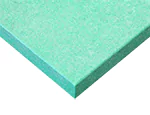

Marine Board withstands the rigors of harsh outdoor marine environments.

Marine Board XL is a lighter, economical version of Marine Board.

King Starboard withstands the rigors of harsh outdoor marine environments.

King Starboard XL is a lighter, economical version of King Starboard.

Marine Board withstands the rigors of harsh outdoor marine environments.

Plastic cutting bits by Onsrud are an industry standard in quality.

Marine Board XL is a lighter, economical version of Marine Board.

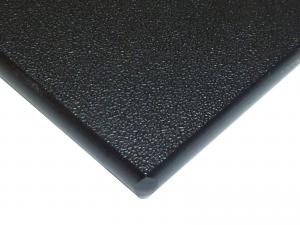

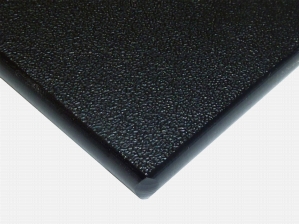

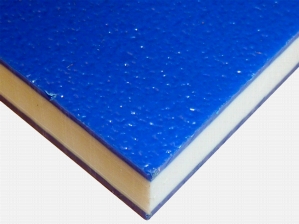

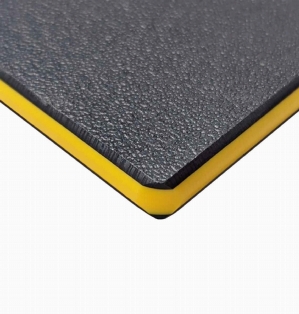

A/S Marine Board is a sure-grip decking material designed for high-traffic areas.

Marine Board withstands the rigors of harsh outdoor marine environments.

A/S Marine Board is a sure-grip decking material designed for high-traffic areas.

Marine Board withstands the rigors of harsh outdoor marine environments.

Marine Board withstands the rigors of harsh outdoor marine environments.

A/S Marine Board is a sure-grip decking material designed for high-traffic areas.

Polymer construction material with desirable architectural specifications for long term durability.

Polymer construction material with desirable architectural specifications for long term durability.

Polymer construction material with desirable architectural specifications for long term durability.

Polymer construction material with desirable architectural specifications for long term durability.

Polymer construction material with desirable architectural specifications for long term durability.

Polymer construction material with desirable architectural specifications for long term durability.

Polymer construction material with desirable architectural specifications for long term durability.

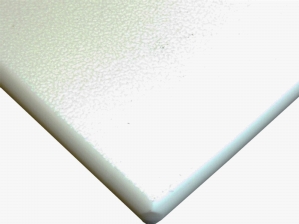

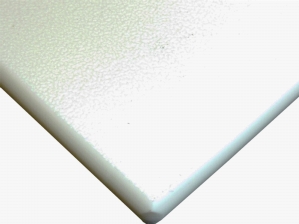

Antimicrobial white HDPE sheets with applications such as medical cabinetry and countertops.

Antimicrobial gray HDPE sheets with applications such as lab cabinets and clean rooms.

Antimicrobial sanshade HDPE sheets with applications such as lab cabinets and clean room panels.

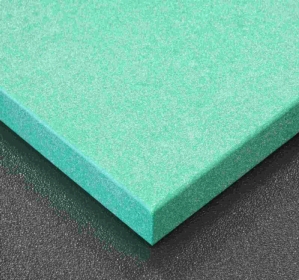

Antimicrobial seafoam HDPE sheets with applications such as medical & doctor office cabinets.

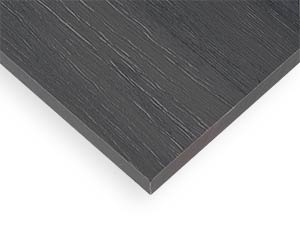

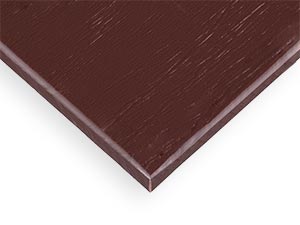

All the beauty of authentic wood without the maintenance and upkeep.

All the beauty of authentic wood without the maintenance and upkeep.

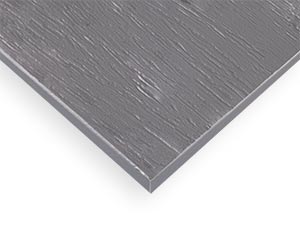

TimberLine HDPE sheets are designed to replace natural and composite wood materials.

TimberLine HDPE sheets are designed to replace natural and composite wood materials.

TimberLine HDPE sheets are designed to replace natural and composite wood materials.

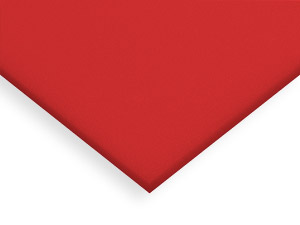

Solid color TimberLine HDPE sheet provides a uniform look to replace wood & composite materials.

Solid color TimberLine HDPE sheet provides a uniform look to replace wood & composite materials.

Solid color TimberLine HDPE sheet provides a uniform look to replace wood & composite materials.

Solid color TimberLine HDPE sheet provides a uniform look to replace wood & composite materials.

Solid color TimberLine HDPE sheet provides a uniform look to replace wood & composite materials.

Solid color TimberLine HDPE sheet provides a uniform look to replace wood & composite materials.

Solid color TimberLine HDPE sheet provides a uniform look to replace wood & composite materials.

HDPE Sheet for Modular Playground Systems.

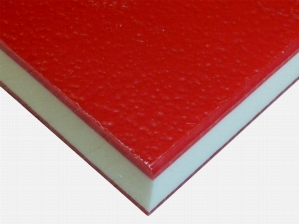

A red HDPE cutting board designed for direct & indirect food contact applications.

A blue HDPE cutting board designed for direct & indirect food contact applications.

A green HDPE cutting board designed for direct & indirect food contact applications.

A yellow HDPE cutting board designed for direct & indirect food contact applications.

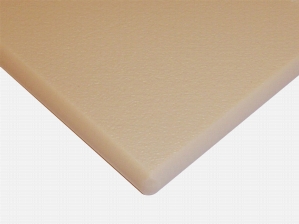

A beige HDPE cutting board designed for direct & indirect food contact applications.

Mostly for signage applications, ColorCore withstands the harshest outdoor conditions.

Mostly for signage applications, ColorCore withstands the harshest outdoor conditions.

Mostly for signage applications, ColorCore® withstands the harshest outdoor conditions.

HDPE designed to replace lead for nuclear shielding applications. Mil-P-23536 certified material.

A very light and extremely tough, chemically resistant plastic.

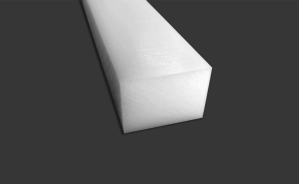

HDPE rods offer a combination of high impact strength, low coefficient of friction, & light weight.

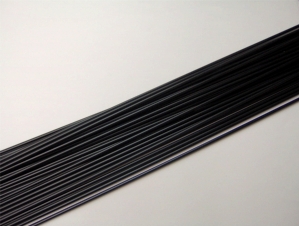

HDPE welding rod is sold by the pound, shipped in 4' straight lengths.

HDPE welding rod is sold by the pound, shipped in 4' straight lengths.

HDPE welding rod is sold by the pound, shipped in 4' straight lengths.

HDPE welding rod is sold by the pound, shipped in 4' straight lengths.

Plastic cutting bits by Onsrud are an industry standard in quality.

Plastic cutting bits by Onsrud are an industry standard in quality.

Saw blades that offer premium performance on hard and soft plastics.

Plastic welding is easy with the Leister plastic welding kit.