CO2 laser compatible craft plastic sheets for New Year decor, art, and other creations.

CO2 laser compatible craft plastic sheets for Valentine decor, art, gifts, and other creations.

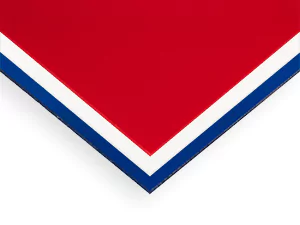

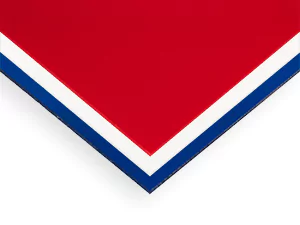

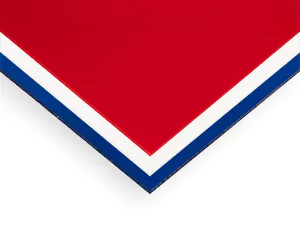

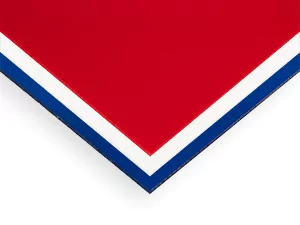

CO2 laser compatible colored craft plastic sheets for patriotic decor & other creations.

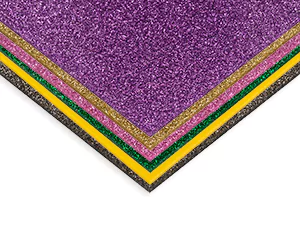

Laser compatible colored craft plastic sheets for Mardi Gras decor and crafts.

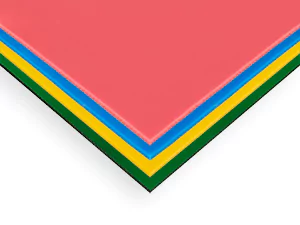

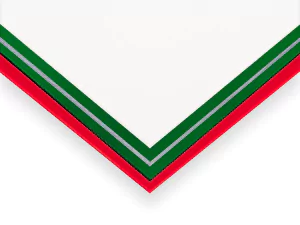

Laser compatible vibrant colored craft plastic sheets for St. Patrick's Day decor and other crafts.

Laser compatible colored craft plastic sheets for Easter decor and crafts.

Laser compatible colored glitter craft plastic sheets for Easter decor and crafts.

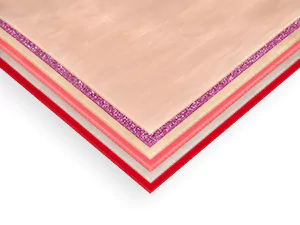

Laser compatible vibrant pastel-colored craft plastic sheets for Easter decor and other crafts.

Laser compatible colored craft plastic sheets for Mother's Day decorations and other adornments.

CO2 laser compatible vibrant colored craft plastic sheets for creating Memorial Day remembrances.

Laser compatible colored craft plastic sheets for Father's Day decorations and other crafts.

LCO2 laser compatible vibrant colored craft plastic sheets for creating patriotic decorations.

Laser compatible vibrant colored craft plastic sheets for creating Labor Day remembrances.

Laser compatible vibrant colored craft plastic sheets for Halloween decor and other crafts.

Laser compatible vibrant colored craft plastic sheets for Thanksgiving decor and other crafts.

CO2 laser compatible vibrant colored craft plastic sheets for Christmas decor and other creations.

CO2 laser compatible glitter craft plastic sheets for Christmas decor and other creations.

CO2 laser compatible glitter craft plastic sheets for Christmas ornaments, decor, & other creations.

CO2 laser compatible craft plastic sheets for Hanukkah decor, art, and other creations.

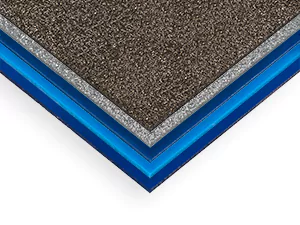

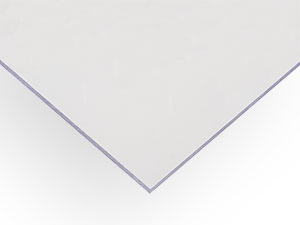

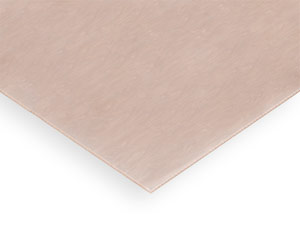

Cast acrylic sheet produces smoother edges and less debris when laser cut.

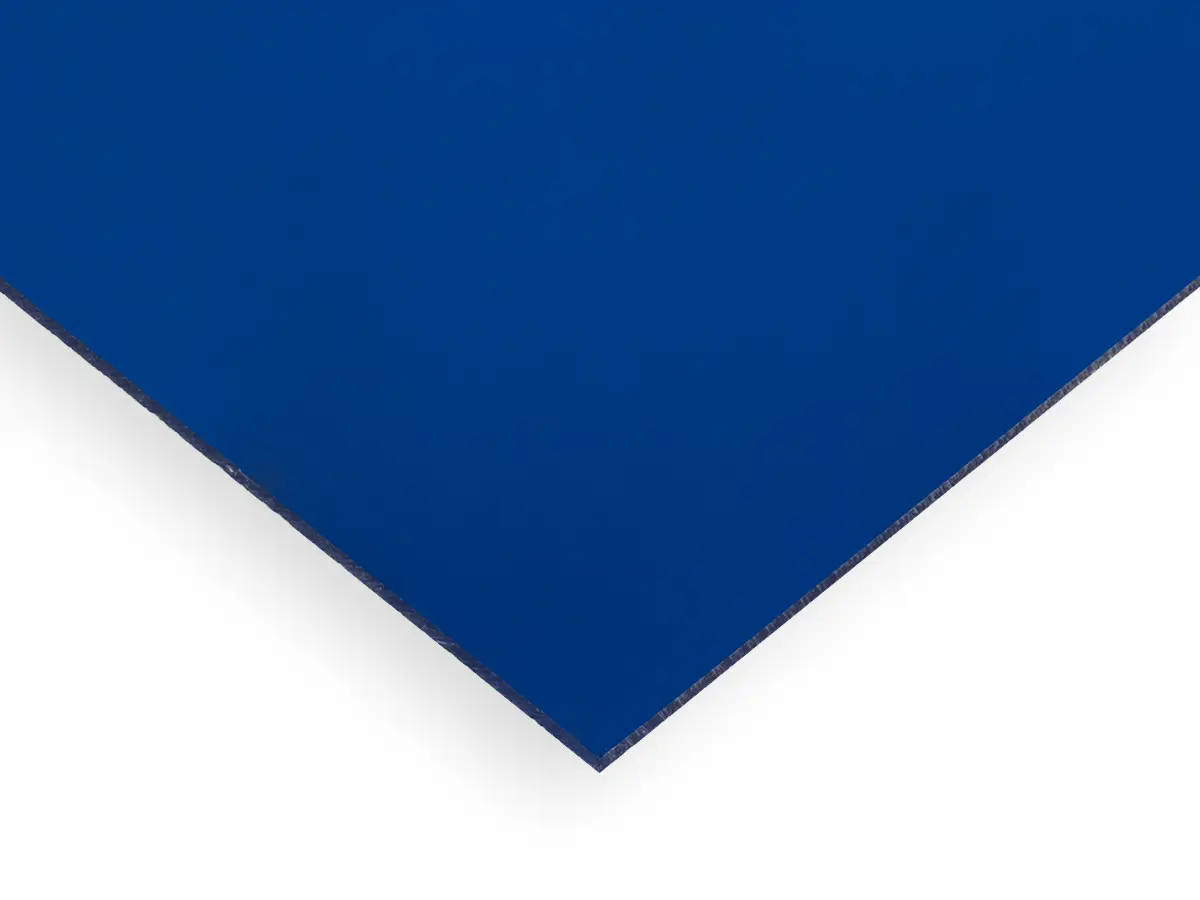

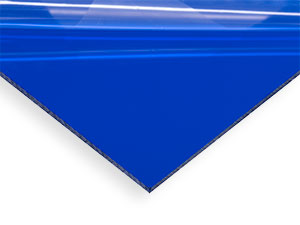

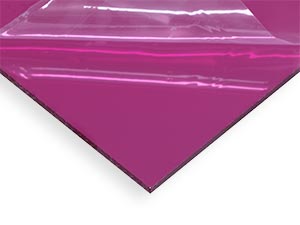

Colored acrylic sheet is a popular and durable material for laser cutting and engraving.

Colored acrylic sheet is impact resistant, lightweight, and fully CO2 laser cutter compatible.

Colored acrylic sheet is impact resistant, lightweight, and fully CO2 laser cutter compatible.

Colored acrylic sheet is impact resistant, lightweight, and fully CO2 laser cutter compatible.

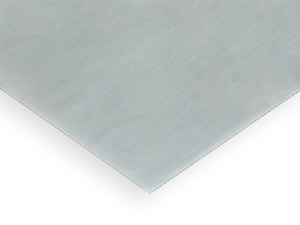

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, & is lightweight.

Cast acrylic sheet produces smoother edges and less debris when laser cut.

Cast acrylic sheet produces smoother edges and less debris when laser cut.

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, & is lightweight.

Colored acrylic serves a multitude of applications from framing pictures to aerospace.

Colored acrylic sheet is a popular and durable material for laser cutting and engraving.

Colored acrylic sheet is impact resistant, lightweight, and fully CO2 laser cutter compatible.

Colored acrylic serves a multitude of applications from framing pictures to aerospace.

Colored acrylic sheet is a popular and durable material for laser cutting and engraving.

Colored acrylic sheet is a popular and durable material for laser cutting and engraving.

Cast acrylic sheet produces smoother edges and less debris when laser cut.

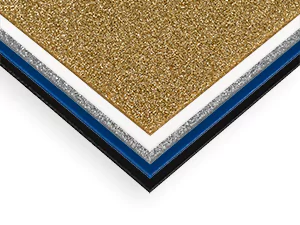

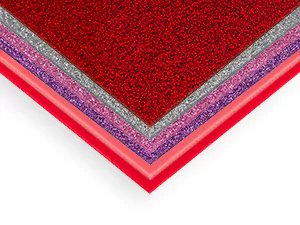

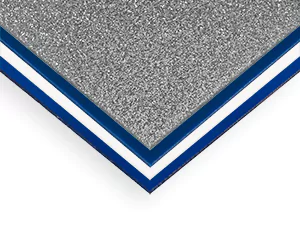

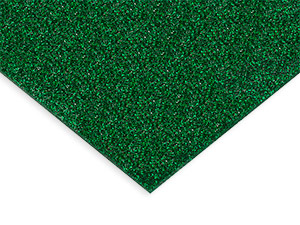

Glitter acrylic sheet is 17 times stronger than glass, durable, weatherable, & lightweight.

Glitter acrylic sheet is 17 times stronger than glass, durable, weatherable, & lightweight.

Glitter acrylic sheet is 17 times stronger than glass, durable, weatherable, & lightweight.

Glitter acrylic sheet is 17 times stronger than glass, durable, weatherable, & lightweight.

Glitter acrylic sheet is 17 times stronger than glass, durable, weatherable, & lightweight.

Glitter acrylic sheet is 17 times stronger than glass, durable, weatherable, & lightweight.

Glitter acrylic sheet is 17 times stronger than glass, durable, weatherable, & lightweight.

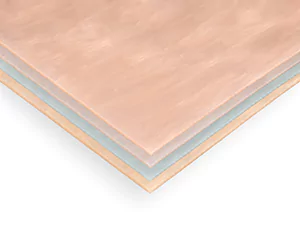

Durable L403 acrylic sheet with an alluring pink marble look.

Durable L404 acrylic sheet with an alluring peach marble look.

Durable L400 acrylic sheet with an alluring white marble look.

Durable L412 acrylic sheet with an alluring blue marble look.

Durable L402 acrylic sheet with an alluring brown marble look.

Craft plastic mirror sheet is laser cutter compatible and made from reflective extruded acrylic.

Craft plastic mirror sheet is laser cutter compatible and made from reflective extruded acrylic.

Craft plastic mirror sheet is laser cutter compatible and made from reflective extruded acrylic.

Craft plastic mirror sheet is laser cutter compatible and made from reflective extruded acrylic.

Craft plastic mirror sheet is laser cutter compatible and made from reflective extruded acrylic.

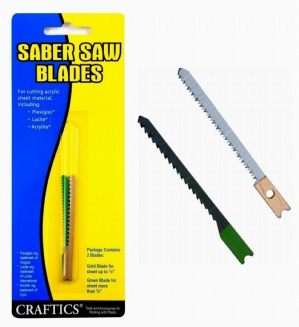

Saber saw blades cut acrylic, polycarbonate, and styrene so smoothly that edges can be polished.

Consumer 24" 55-Watt Plastrip Heater.

Onsrud 70-500 Series HSS High Speed Steel Two Flute Fractional Drill Bits for Plastic.

WARNING: The products on this page can expose you to chemicals including Ethyl acrylate, CAS 140-88-5, which are known to the State of California to cause cancer. For more information go to www.p65warnings.ca.gov.