« Back to News

Fatigue-Resistant Material Solutions for Enhancing Efficiency in Food Processing Equipment

The food and nut processing industries continue seeking ways to improve the efficiency of vibratory processing equipment like shaker tables and utilize fatigue-resistant material solutions that reduce downtime and extend the lifespan of processing equipment. Interstate Advanced Materials supplies NorPLY™ 1002, Ultra High Molecular Weight Polyethylene (UHMWPE) sheet, and machined parts tailored for the food and nut processing sectors to help facilitate more efficient and effective processing operations.

The food and nut processing industries continue seeking ways to improve the efficiency of vibratory processing equipment like shaker tables and utilize fatigue-resistant material solutions that reduce downtime and extend the lifespan of processing equipment. Interstate Advanced Materials supplies NorPLY™ 1002, Ultra High Molecular Weight Polyethylene (UHMWPE) sheet, and machined parts tailored for the food and nut processing sectors to help facilitate more efficient and effective processing operations.

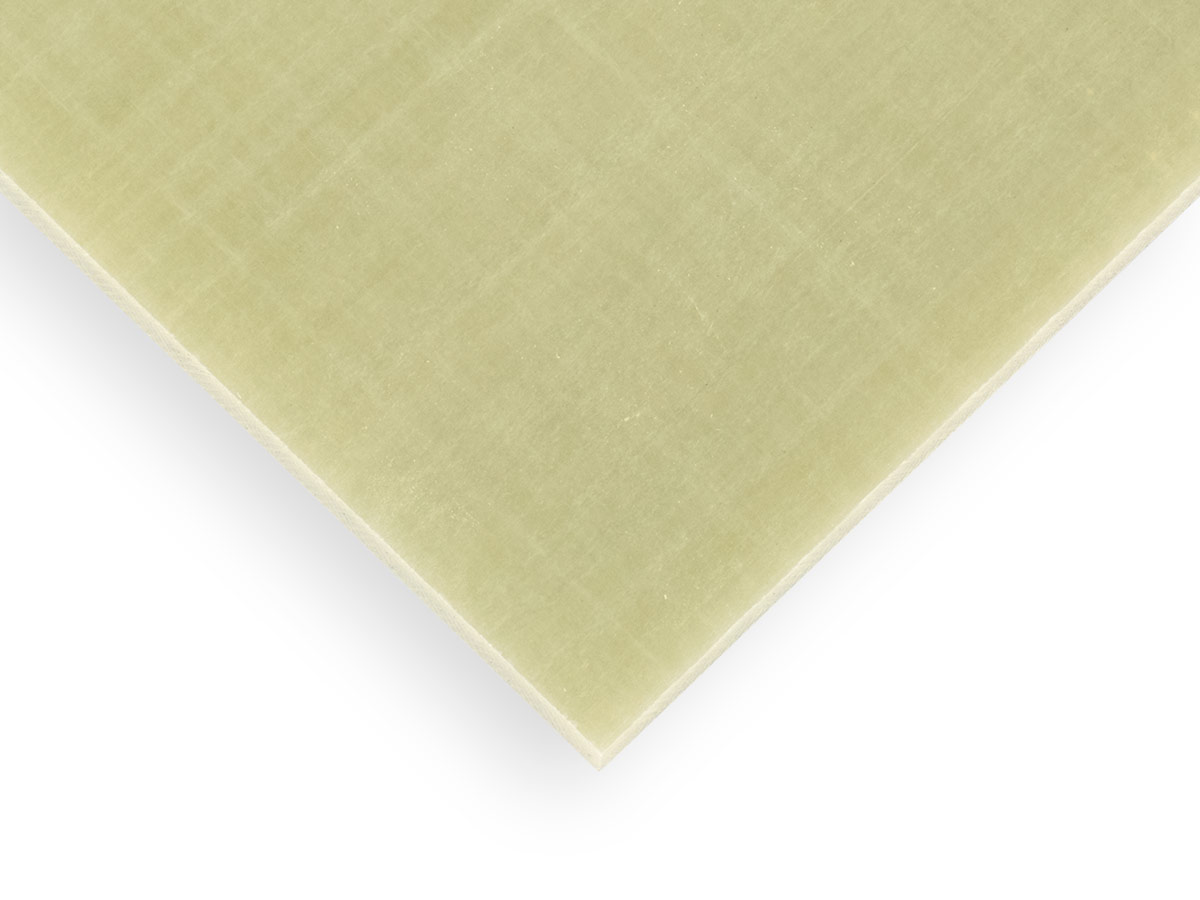

Interstate Advanced Materials is an exclusive supplier of the glass epoxy composite laminate sheet NorPLY™ 1002. NorPLY™ 1002 is engineered to optimize performance under load and delivers numerous advantages for shaker springs in shaker tables and other vibratory equipment. NorPLY™ combines continuous E-glass filaments with an epoxy resin for a fatigue-resistant material with greater energy storage than 1060 steel that can effectively absorb and dampen vibrations generated by shaker tables. It is able to undergo many load cycles without failing, surpassing other composite materials as well as steel. NorPLY™ provides a significant reduction in component weight that ranges from 10% to 60% when used to replace steel components. Its resistance to chemicals and corrosion further extends its performance lifespan.

Ultra-High Molecular Weight Polyethylene (UHMWPE) is a trusted industry material solution for detwigger screens used in shaker tables. UHMW's strength and light weight allow detwigger screens to withstand the constant mechanical stresses and impacts that occur in food and material separation processes. Outstanding resistance to abrasion enables it to withstand wear caused by particles and debris and extends its service life over alternatives like steel or rubber. UHMW's low coefficient of friction and non-stick properties facilitate the smooth flow of materials across its surface, preventing clogs, jams, or buildup, and help optimize the efficiency of food separation processes.

Interstate Advanced Materials offers custom part fabrication for OEM replacements and welding solutions for the food processing, nut processing, and agriculture industries. The company's services encompass custom CNC routing, plastic welding, and custom fabrication. Interstate Advanced Materials specializes in crafting precision custom components for diverse applications, including processing equipment, sorting machinery, conveyors, and packaging systems, and can reverse engineer or fabricate based on OEM prints and drawings.

Explore Interstate Advanced Materials' comprehensive selection of food processing equipment materials and custom fabrication options. Food, nut, and agriculture professionals looking to reduce their material costs can save 30%+ on NorPLY™, UHMW-PE, and more with an Interstate Advanced Materials membership. To learn more about fatigue-resistant materials for food processing equipment, call a material expert at (800) 742-3444.

Interstate Advanced Materials is a full-line distributor of sheet, rod, tube, bar, film, profile, and accessories, tools, and care products. With 10 locations nationwide and an online sales and support team, Interstate Advanced Materials provides full sheets and pallets, simple cut-to-size service, and complex CNC manufacturing. Interstate Advanced Materials is known for its reputation of selling high-quality products, providing excellent customer service, and superior technical support. Our products and services are available using the safe, secure, and convenient purchasing system on the Interstate Advanced Materials website. For instant help, we're always a phone call away at (800) 742-3444.