Thermoforming materials play a crucial role in the firearm industry due to their versatility, enabling the creation of custom grips, gun holsters, magazine carriers, and other accessories. Thermoplastics like Boltaron® and Kydex® are popular for their durability and moldability into precise holster or sheath shapes, while thermoset materials like phenolic are used in the creation of knife handles and firearm grips.

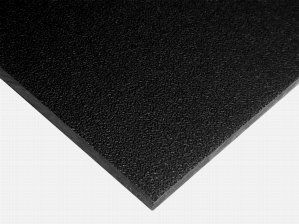

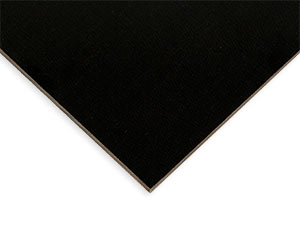

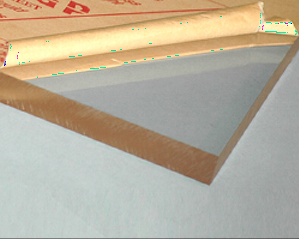

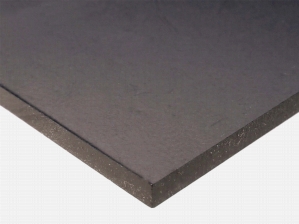

- Boltaron® is a chemically resistant thermoplastic with exceptional qualities that make it well-suited for the production of custom gun holsters, knife sheaths, and magazine carriers. Boltaron® exhibits excellent formability, allowing for precise and intricate molding that enables manufacturers to create holsters with a custom fit for specific firearm models and ensure a secure and snug hold. Its high impact resistance provides fantastic protection for the holstered firearm and stands up to the rigors of daily use. Holsters made from Boltaron® benefit from its chemical resistance and maintain their integrity even when exposed to excess oil or solvents from regular cleaning and maintenance. Boltaron® also has low friction properties, enabling a smooth draw. Interstate Advanced Materials carries Boltaron® Carbon Fiber and can custom color match any color, including Desert, OD Green, and Flat Dark Earth (FDE).

- Kydex® is another versatile thermoplastic extensively utilized in the firearms industry for crafting holsters, knife sheaths, and various firearm accessories. Its reputation for rigidity and durability makes it a preferred choice among firearm enthusiasts and professionals alike. Kydex® excels in maintaining its shape under demanding conditions, providing a secure and consistent fit for a wide range of guns and knives. This quality ensures that the holster or sheath not only offers a precise fit but also retains its form, even during rigorous activities or adverse environments. Its low friction properties provide users with a smooth and efficient draw. Kydex® is easily cleaned and maintained and is available in many patterns and colors that allow for personalized custom holsters that match the user's style and preferences.

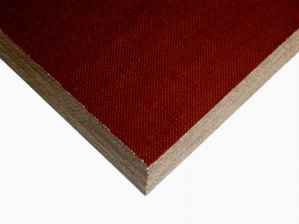

- Phenolics, also known by the brand name Micarta, are thermoset materials utilized in the manufacturing of firearm grips and knife handles due to their resistance to wear, chemicals, and impact. Phenolic grips and handles are known for their durability and ability to withstand a variety of environments. Specific phenolic grips and handles are chosen based on the desired texture, appearance, and performance requirements of the user:

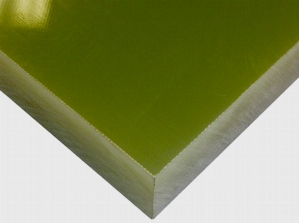

- G10 glass epoxy phenolic is preferred for firearm grips and knife handles for its strength, light weight, and resistance to moisture and chemicals. It provides greater customizability than other grades of phenolic, with different textures and patterns available.

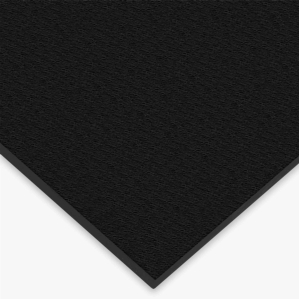

- Canvas phenolic features a textured surface that provides an enhanced grip on firearms and knives in challenging conditions. Like G10, it is tough, durable, and resistant to wear.

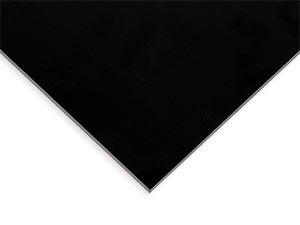

- Linen phenolic offers a smoother-feeling grip/handle for a better balance of comfort and durability. Like G10 and canvas grades, it is also durable and resistant to wear.

Thermoplastics are invaluable for prototyping in the firearms industry and allow for swift and cost-effective iterations on design for firearm components. ABS and PVC offer a balance of durability and moldability, enabling the rapid and cost-effective creation of detailed and functional prototypes that allows manufacturers to test and refine designs before committing to more expensive production materials.

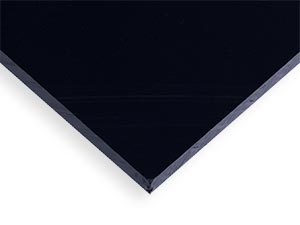

- ABS (Acrylonitrile Butadiene Styrene) is a widely used thermoplastic for prototyping within the firearm industry, providing a range of advantages for manufacturers and designers. Its popularity stems from its well-balanced properties, making it suitable for creating prototypes of various firearm components. ABS is known for its durability, impact resistance, and ease of fabrication and is employed when prototyping various firearm parts like grips, stocks, and non-load-bearing components. ABS' robustness allows prototypes to withstand realistic testing conditions and help simulate the wear and tear that firearms may experience. This is crucial for evaluating the performance, fit, and durability of the designed components before moving on to more expensive production materials.

- PVC (Polyvinyl Chloride) is occasionally used for prototyping in the firearm industry, particularly for certain components that do not face high structural or load-bearing requirements. PVC offers unique advantages in the prototyping process, primarily due to its excellent moldability, cost-effectiveness, and ease of processing. Its cost-effectiveness allows for rapid iteration during the design and development phase without incurring significant expenses. Though it lacks the same impact resistance as ABS, PVC is used for prototypes where durability and structural strength are not primary concerns. Prototyping with PVC allows for the evaluation of fit, form, and aesthetic considerations before finalizing designs for production.

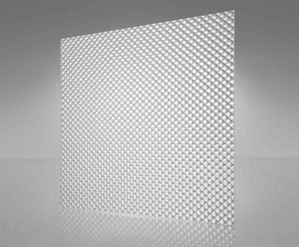

Thermoplastics are an integral part of shooting range design, equipment, and shooting targets. Materials like High Impact Polystyrene and fluted polypropylene have superior impact resistance to paper or cardboard targets and are a recyclable and cost-effective option for shooting range operators. Interstate Advanced Materials offers routing services for target shapes - send us a drawing or photo or give us a call for a speedy, professional quote.

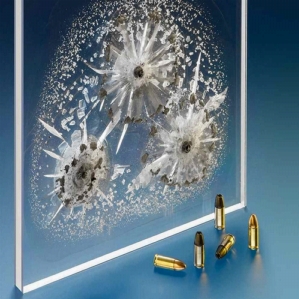

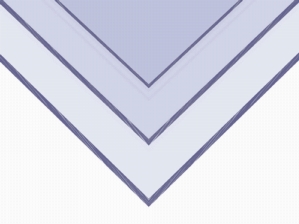

- Acrylic, also known by the brand name Plexiglas, is known for its clarity and sees use in shooting range barriers or viewing windows. Its transparency allows for clear visibility and enables range officers and spectators to observe shooting in a controlled and safe environment. Bullet-resistant grades of acrylic to contain or mitigate the impact of projectiles and improve range safety are available.

- Polycarbonate is known for its durability, impact resistance, and transparency. Virtually unbreakable, this material is used in shooting ranges for dividers between shooting lanes and as windows for observation ports, control rooms, or viewing areas. Bullet-resistant grades of polycarbonate have been UL-rated for ballistic impacts and will not shatter.

- High Impact Styrene (HIPS) is commonly used in shooting range targets due to its cost-effectiveness, impact resistance, and versatility. HIPS enables shooting ranges to maintain a steady supply of targets that withstand hits from various calibers during shooting practice without straining budgets. Styrene is lightweight, heat formable, and easily fabricated into a diverse set of diverse target shapes and sizes. It can withstand multiple impacts without significant damage, allowing each target to be reused and further increasing the material's cost-effectiveness. Styrene has excellent ink adhesion and can be colored or painted for custom target designs, enhancing visual feedback for training scenarios or competitions.

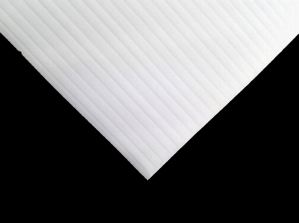

- Fluted Polypropylene, also known as Polypropylene Twinwall or the brand name Coroplast, is a corrugated material that is excellent for shooting target backing. Lightweight yet durable, fluted polypropylene absorbs and disperses the energy from bullet impacts to maintain a consistent surface for targets. It is weather- and moisture-resistant, making it suitable for outdoor use. Fluted polypropylene is cost-effective and is a good choice for shooting range operators looking for a budget-friendly durable solution for target backing. Like styrene, fluted polypropylene is easily shaped and formed into the necessary sizes or shapes required for the range.

Thermoplastics like Ultem® and acetal are favored in optics mounts for firearms due to their high strength, light weight, and versatility, offering manufacturers the ability to achieve durability and precise designs for effective and reliable optic installations.

- Ultem® is a high-performance thermoplastic with exceptional chemical resistance and strength. The optics industry uses 30% glass-reinforced Ultem®to craft scopes. Glass fibers enhance Ultem®'s already impressive properties, increasing its strength, stiffness, and heat resistance. It is an ideal choice for optics mounts where durability, stability, and resilience to elevated temperatures is critical.

- Acetal is utilized in optics mounts for firearms due to its high strength, stiffness, and low friction properties. It offers structural integrity, low friction for smoother and more precise adjustments, and a resistance to chemicals that allows it to withstand solvents used in cleaning and maintenance. Acetal's dimensional stability provides more reliable optic alignment as it will not warp or deform in a diverse set of environments.

In the creation of animal call devices, thermoplastics like acrylic and acetal are popular choices.

- Acrylic, also known by the brand name Plexiglas, is known for its clarity and acoustic resonance. Animal calls made with acrylic produce clear and crisp sounds. Weather resistant, durable, and heat formable, acrylic is a robust and long-lasting material that can enhance the performance of animal calls.

- Acetal's excellent machinability allows for the intricate designs and precise mechanisms found in animal calls. Though not as acoustically resonant as acrylic, its toughness, low friction and wear properties, and resistance to chemicals make it well-suited for the moving parts and mechanical components found within animal calls.

For a full list of available acrylic colors, please see our acrylic colors brochure.

Thermoplastics are commonly used in the construction of firearm cabinets due to their versatility, durability, and ease of fabrication. Materials like acrylic see use in cabinet window panes, while polypropylene (PP) and HDPE, including its woodgrain variants, are chosen for use in cabinet construction over wood for their durability, chemical resistance, and longevity.

- Acrylic's clarity, transparency, and impact resistance allows it to serve as cabinet window panes to safely showcase guns while protecting them from impacts. Its light weight makes it easy to handle and install, while its UV resistance reduces the potential for yellowing or discoloration over time when exposed to sunlight.

- Polypropylene (PP) is a durable and chemical resistant material for firearm cabinets and racks. Polypropylene's durability gives it the ability to withstand the weight and wear of firearms, while its resistance to chemicals allows it to handle the solvents, oils, and chemicals associated with firearm maintenance without corroding or degrading. Polypropylene is relatively cost-effective compared to similar materials.

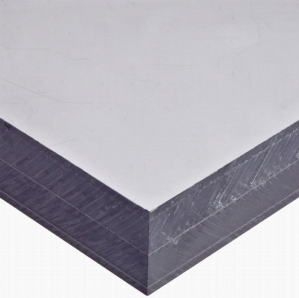

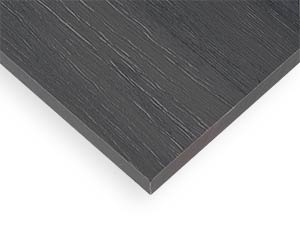

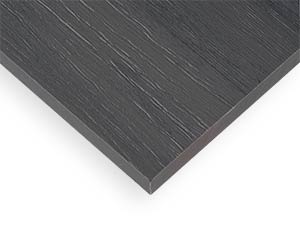

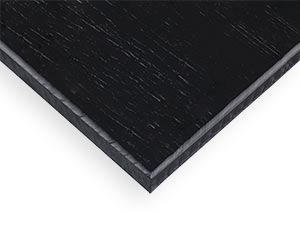

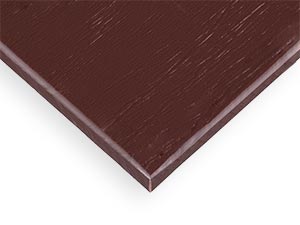

- High-Density Polyethylene (HDPE) a tough, durable material well-suited for use in firearm cabinets and safes. Like polypropylene, HDPE's durability ensures the longevity of cabinets as it can bear the weight and potential abrasions associated with firearms. Its chemical resistance guards against degradation when exposed to cleaning agents and gun oils to maintain the integrity of the storage space. HDPE's inherent resistance to moisture prevents rust or corrosion in environments prone to humidity, while its machinability allows for the fabrication of customized storage solutions tailored to specific firearm types and sizes.

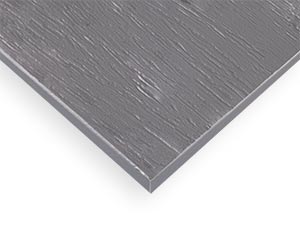

- Woodgrain HDPE is designed to mimic the aesthetics of wood while offering the durability, moisture resistance, chemical resistance, and low maintenance of HDPE. It provides a natural look for firearm cabinets, racks, or safes without any of wood's drawbacks. Outside of cabinets and safes, woodgrain HPDE has seen use in shooting range furniture and outdoor equipment such as benches, tables, or target stands for attractive and longer-lasting products.

When it comes to bag stiffeners, different thermoplastics like nylon, polypropylene, HDPE, and LDPE provide varying levels of support, flexibility, and rigidity and are best chosen depending on the application the bag will be used for.

- Nylon is a strong, abrasion resistant thermoplastic with good flexibility. It is used as a bag stiffener when strength and durability are crucial, and can provide excellent support without adding excessive weight to the bag.

- Polypropylene (PP) is a lightweight and rigid material with excellent chemical resistance. Polypropylene is typically used when a balance of rigidity and light weight is required, and its resistance to chemicals can be beneficial.

- High-Density Polyethylene (HDPE) is a thermoplastic material with high stiffness, impact resistance, and strength. Resistant to chemicals and moisture, HDPE is used as a bag stiffener for bags that may undergo rough handling or need to maintain shape.

- Low Density Polyethylene (LDPE) is a flexible, lightweight, and impact resistant plastic. Like HDPE, it is resistant to moisture but is better suited as a bag stiffener for applications where more flexibility is key. It provides support while allowing the bag to maintain a certain level of pliability.

Thermoplastics form an essential part of hunting gear and equipment. Their durability, light weight, and overall resistance to weather and chemicals make them a natural fit over metal for increased longevity and better portability over longer distances. Thermoplastics like ABS, HDPE, and LDPE are moldable and formable, allowing for custom parts and flexible designs for decoys, stands, containers, and other gear or accessories. Thermoplastics are often more cost-effective than metals or composites.

- ABS (Acrylonitrile Butadiene Styrene) is a widely utilized thermoplastic in the manufacturing of hunting gear, offering a combination of toughness, impact resistance, and versatility. Its exceptional impact resistance ensures that hunting equipment, such as firearm accessories, protective gear, or storage containers, can endure rugged outdoor conditions without compromising functionality. The durability of ABS makes it suitable for components subjected to wear and tear during hunting activities. Its relatively lightweight nature enhances the portability of gear, especially accessories and items that hunters carry on expeditions. ABS's moldability allows for the creation of custom-designed components, contributing to the adaptability and ergonomic considerations of the equipment. The material's good chemical resistance ensures that ABS-based hunting gear can withstand exposure to cleaning agents, oils, and other substances commonly used in firearm maintenance. With a variety of aesthetic options available, ABS enhances the overall appeal of hunting gear, providing both functionality and visual appeal for outdoor enthusiasts.

- High-Density Polyethylene (HDPE) is a tough, rigid, and durable material with excellent resistance to chemicals and water. Renowned for its toughness and durability, HDPE is used in equipment such as decoys, gadget storage, folding chairs, and general storage containers, ensuring longevity and resilience in potentially harsh outdoor conditions. HDPE's chemical resistance makes it suitable for gear that may encounter cleaning agents or oils during firearm maintenance. HDPE is moldable and formable into custom-designed components for equipment.

- Low Density Polyethylene (LDPE) is a similar material to HDPE, but is generally more flexible and ductile. This makes it a better fit than HDPE for hunting gear or accessories where the increased flexibility is required. LDPE is also lighter than HDPE and is generally more cost-effective while providing similar properties and may be a better choice for applications that don't require HDPE's superior rigidity.

In the realm of hunting applications, both acrylic and polycarbonate serve as valuable materials for lighting solutions. Acrylic excels in optical clarity and even light diffusion, while polycarbonate prioritizes durability.

- Acrylic is known for its clarity and light transmission properties. Often used as the cover for tactical rail mounted lights, flashlights, and other portable light sources, acrylic diffuses light evenly to create a soft and uniform illumination to enhance visibility without causing glare. Acrylic is UV resistant and will resist the yellowing caused by prolonged exposure to sunlight.

- Polycarbonate is another thermoplastic known for its clarity and light transmission properties. A virtually unbreakable material, polycarbonate can be used as a protective cover for portable light sources like flashlights, rail mounted lights, and more.

Thermoplastics like ABS, HDPE, and woodgrain HDPE have risen in popularity for treestands. Their moldability, light weight, and balance of strength, impact resistance, and weatherability allows for the creation of reliable and efficient treestand mainframes and accessories.

- ABS (Acrylonitrile Butadiene Styrene) features durability and moldability that make it a good fit for various accessories and safety railings or guards on treestands. ABS can be incorporated into footrests or shooting rails to provide a stable and durable surface to rest their feet or steady their aim. ABS holders for binoculars, rangefinders, or firearm rests can help customize the treestand to the hunter's preferences. ABS can also be used as a part of cable management systems as a durable cover to protect the cables or straps that attach to the tree.

- High-Density Polyethylene (HDPE) is a tough, rigid, and durable material with excellent resistance to chemicals and water. HDPE is quiet in operation compared to metal, minimizing the potential noise and disturbance during a hunt. Low maintenance and exceptional weatherability allow HDPE to endure the elements with minimal cleaning or upkeep necessary.

- Woodgrain HDPE mimics the aesthetics of wood but retains the durability, moisture resistance, chemical resistance, and low maintenance of standard HDPE. The more natural colors of woodgrain HDPE help it blend in with trees when used as a part of treestands and its superior weatherability to metal or wood extends its lifespan even in harsher outdoor environments.