Durable & UV-resistant panels for data centers, server farms, and server installations.

Durable & UV-resistant panels for hot and cold aisle containment systems.

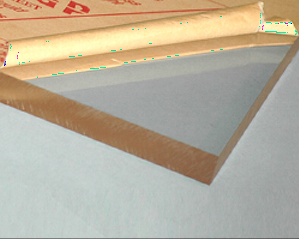

Acrylic sheet is 17 times stronger than glass, has excellent clarity, durability, and is lightweight.

Extruded Acrylic has moderate properties, easy handling and processing, and low cost.

WARNING: The products on this page can expose you to chemicals including Bisphenol A, CAS 80-05-7, which are known to the State of California to cause birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

WARNING: The products on this page can expose you to chemicals including Ethyl acrylate, CAS 140-88-5, which are known to the State of California to cause cancer. For more information go to www.p65warnings.ca.gov.