High Impact Polystyrene (HIPS) and fluted polypropylene are popular valued materials in the granite and stone countertop industries for creating countertop templates due to their unique properties. Styrene is known for its durability, light weight, and flexibility, which make it easy to cut and shape to precise dimensions for accurate countertop fitting. Its superior impact resistance and reusability compared to similar template materials enhances its cost efficiency. Fluted polypropylene, commonly known as Coroplast, shares similar lightweight and durable characteristics but is also water-resistant, making it particularly useful in environments that harbor a large amount of moisture. Both materials are excellent for producing precise and reliable templates, helping to reduce errors in the installation process and ensure that countertops are perfectly aligned and cut in both residential and commercial settings.

High Impact Polystyrene (HIPS) is a popular material for creating countertop templates due to its excellent combination of durability, light weight, and flexibility. Its enhanced durability makes it resistant to the impacts that may occur during handling and transport. Styrene is lightweight, which makes it easy to maneuver and position for on-site templating processes. Its flexibility allows for precise cuts and easy shaping to ensure accuracy in measurements and fit. Styrene strips can even be rolled up once assembled for easy transport via car to the fabrication facility, removing the associated costs of moving templates made from other materials like wood or Coroplast in a large truck. This makes High Impact Polystyrene an economical choice for both high-volume projects and customized countertop installations. Styrene can be glued and cut on-site, allowing for easy modifications that can account for complex designs that include sink cutouts or decorative edges. High Impact Styrene's properties, including its precision in cutting and shaping, make it the superior cost-effective material for countertop templating that balances performance with affordability and ease of use.

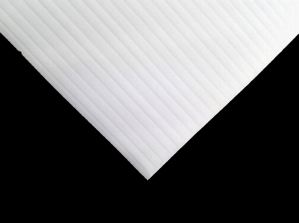

Like High Impact Polystyrene, fluted polypropylene has several properties that make it a suitable material for countertop templates. Also known by the brand name Coroplast, fluted polypropylene has excellent durability and is water resistant, making it a better fit than HIPS for areas where prolonged exposure to moisture is likely. It can be glued or stapled to create the template, and the staples may be removed to allow for the reuse of the material. These properties make it better suited for repeated use in a wider variety of environments than High Impact Polystyrene. Like styrene, fluted polypropylene is similarly lightweight, but is overall less flexible and cannot be rolled or folded as easily. Among the common options for templating materials, fluted polypropylene provides a good middle ground between the basic paper or cardboard materials and the more expensive digital templating solutions.

Interstate Advanced Materials offers silicone sealants as well as adhesives for use in adhering countertops to cabinet tops. These sealants can bond slabs together at the seams, eliminating the gap between the two pieces and creating a strong seal. Silicone adhesive is widely used throughout the countertop industry for its waterproof properties and strong bonding capabilities. Once bonded, silicone adhesive can absorb impacts and accommodate slight movements of the countertop due to temperature changes or weight distribution without cracking. Its water resistance makes it ideal for use in kitchen and bathroom countertops and prevents water from accumulating in the seams, which could lead to mold growth. It is also resistant to household chemicals and cleaning agents, ensuring that the bond will not degrade easily and will remain strong even when subjected to rigorous cleaning. This makes silicone adhesive ideal for solid surface countertops. Silicone sealants are offered in clear and white versions.