Cut-To-Size Items are Non-Returnable!

As per our Shipping and Returns Policy, custom cuts and fabricated parts are non-returnable. If you need an over- or undersized item, note it under \"Comments\" during Checkout. Cut-to-size orders have an acceptable cut tolerance of 1/8" (0.125"), so clarify if the adjustment is to be made on the (+) or (-) side of the saw blade. Please review our full return and shipping policy here.

Measure Twice, Cut OnceSince custom cuts and fabricated parts are non-refundable, be very careful while measuring your dimensions. As each cut is nominal, even the slightest miscalculation could be costly.

How to Use a Measuring TapeExtend your tape measure several inches to find the 1 and 2 inch markers. In between the inch markers you’ll find 16 equally spaced tick marks.

Measure by counting the increments beyond the nearest inch. As the increments decrease, so does the length of the mark. For example, 1/2\" has a bigger mark than 1/4\" which has a bigger mark than 1/8\". The smallest mark follows at 1/16\". Please be aware that some measuring tapes may have even smaller increments.

Features of a Measuring Tape: Sliding End HookThe sliding end hook is designed for two different types of measurements. An outside measurement (where the hook of the tape hangs over an edge), requires the hook to slide out a bit to account for the thickness of the material. When making an inside measurement (where the hook will push up against a surface), the clip slides in, again, accounting for its thickness. The measuring tape self-adjusts to guarantee an accurate measurement (as far as the tape is concerned).

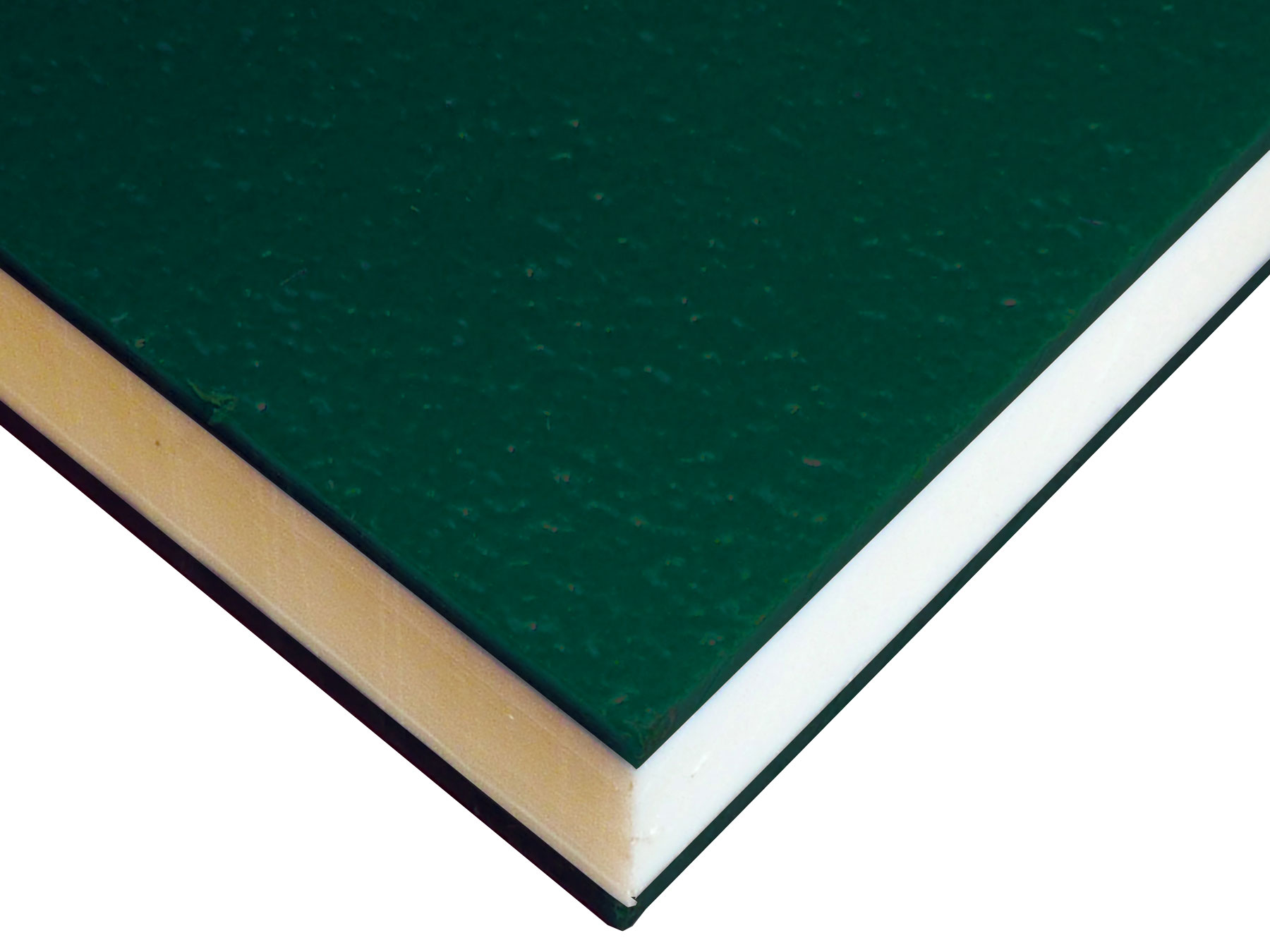

HDPE ColorCore® | Green/White/Green

ColorCore® High-density Polyethylene (HDPE)

Select your custom cut sizes:

Description

HDPE ColorCore® with a white core and green cap is a versatile, durable and colorfast plastic used commonly for signage applications. It is environmentally and UV stabilized to withstand even the harshest outdoor conditions and can be used in areas that are washed often or regularly exposed to moisture. HDPE ColorCore® can be fabricated using common woodworking tools and techniques. Colors Cap Thinness Durability Impact Resistance UV Stabilization and Weather Resistance

Unlike other signage materials where color is achieved through lamination, HDPE ColorCore® is manufactured by a unique PolyFusion�?� process that fuses various layers of color into a single homogeneous sheet, which embeds color into the plastic. HDPE ColorCore® is guaranteed not to delaminate, crack, or chip and is available in several gauges and many matched and paired colors. Custom colors are available by order; large minimums may apply for custom runs.

ColorCore®'s thin cap layers (approximately 10% of the thickness on each side) and bright primary colors (approximately 80% of the core) make ColorCore® ideal for signage, marine, playground and other recreational applications. Due to its thin cap, ColorCore® sheets are easy to engrave and machine.

ColorCore® sheets are made with high-impact-resistant polymers in order to handle more day-by-day abuse than conventional sign materials. ColorCore® is environmentally stabilized for high-pressure accessories and components in both commercial and industrial applications. Due to its unique composition, ColorCore® outlasts other standard signage-such as wood and vinyl signs-with virtually zero maintenance.

ColorCore® resists marking by pens, markers and spray paint, and can be cleaned easily with regular household cleaners. Its durable textured finish also resists scratching and marring.

This product is UV stabilized to resist deterioration in harsh outdoor environments, making ColorCore® the perfect signage material. And unlike other signage materials, it's water resistant and won't delaminate, swell, crack or rot.

- Weather resistant

- Impact resistant

- Environmentally and UV stabilized

- Easy to fabricate and machine

Specifications

Specific Gravity (g/cc): 0.955

Water Absorption: 0.10% @ 24H

Density: .955 g/cc

Tensile Strength: 4100 psi @ Yield

Tensile Modulus: 255 ksi

Flexural Modulus: 185 ksi

Flexural Strength: 3800 psi

Elongation: 600% @ Break

Izod Impact Strength: 1.1 ft-lb/in.

Hardness: Shore D68

Heat Deflection Temp: 167°F @ 66 psi

Vicat Softening Temp: 253°F

UL94 Flammability: HB

Frequently Asked Questions

What is Interstate Advanced Materials's Shipping Policy?

Our shipping policy can be found here and orders placed for non-cut-to-size stock items typically ship within 3 working days.

Is Interstate Advanced Materials site secure?

Absolutely. Your information is passed through our https site when you make a purchase. Your Credit Card is never stored on file.