Ingeniously simple and compact plastic welder for polyethylene (PE) and polypropylene (PP).

Achieve perfect seam quality with one compact extruder (product # 148.396).

Compact, ergonomically designed workhorse (product # 127.215).

Triac AT - an intelligent and robust hot-air hand tool for plastic welding and shrinking.

Hot-air hand tool primarily used in welding and plastic fabrication applications.

Suited for use in container and pipeline manufacturing and civil engineering.

The Leister DIODE PID offers electronically regulated welding temperature and an external air supply, making it perfect for mobile installation work.

A high-powered welding tool with an external air supply. The tool's rotary temperature controls help to produce consistent, quality welds with every use.

Leister's® most powerful hand tool, suitable for construction sites.

Lighter, quieter, and more durable than any heat gun on the market.

The most compact hand tool from Leister®, the Hot Jet S.

Ideal for welding in small spaces.

Optimized for draw welding.

Optimized for draw welding.

Compact and lightweight, the MINOR is designed to provide mobile air supply to Leister hot-air hand.

For flameless shrinking of pallets and bulk goods.

LEISTER GHIBLI offers strain-free operation while welding or shrinking with hot-air.

The ROBUST combines a compact design with significant power, offering airflow potentials up to 46 cf.

Heating element for Leister Hot Jet S.

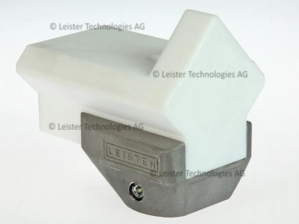

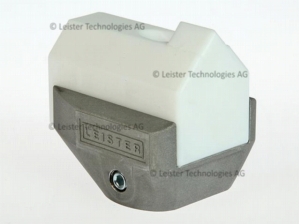

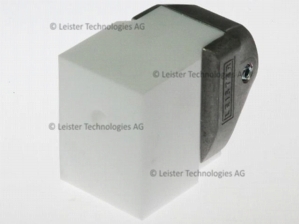

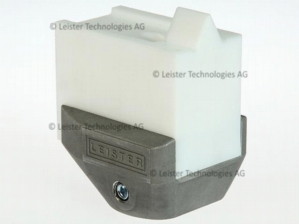

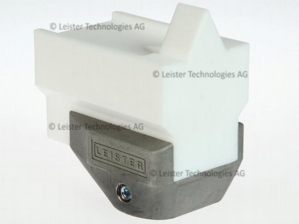

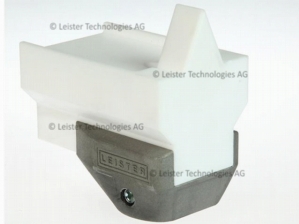

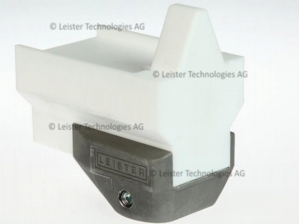

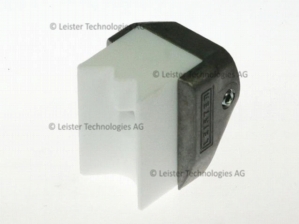

Welding Shoe for the Leister® FUSION 1 Extrusion Welder

Welding Shoe for the Leister® FUSION 1 Extrusion Welder

Welding Shoe for the Leister® FUSION 1 Extrusion Welder

Welding Shoe for the Leister® FUSION 1 Extrusion Welder

Welding Shoe for the Leister® FUSION 1 Extrusion Welder

Welding Shoe for the Leister® FUSION 1 Extrusion Welder

Welding Shoe for the Leister® FUSION 1 Extrusion Welder

Welding Shoe for the Leister® FUSION 1 Extrusion Welder

Leister® Welding Shoe 145.816

Leister® Welding Shoe 145.817

Leister® Welding Shoe 145.903

Leister® Welding Shoe 145.905

Leister® Welding Shoe 145.909

Leister® Welding Shoe 145.915

Leister® Welding Shoe 145.916

Leister Welding Shoe 146.645

Welding Shoe 146.649

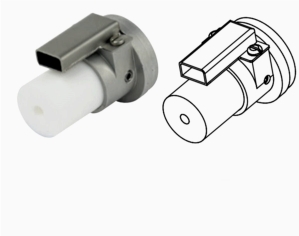

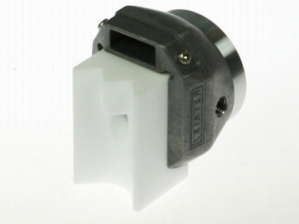

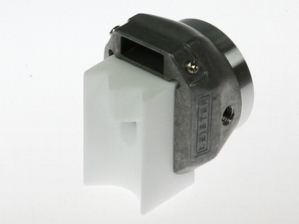

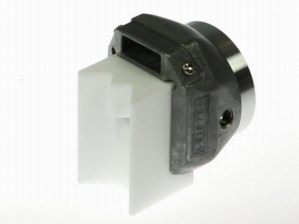

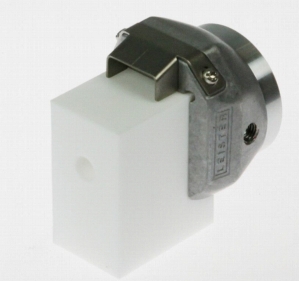

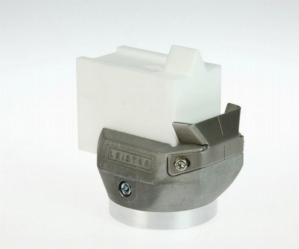

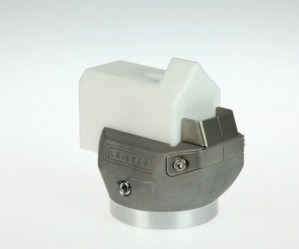

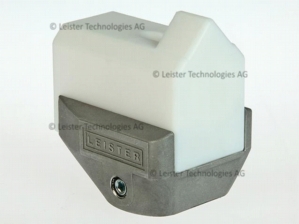

Leister 148.816 Angle Adapter

Leister 148.817 Angle Adapter

Leister Welding Shoe 146.643

Position 6h and 14mm O.D. Hot Air Tube for the Leister Weldplast S1

Position 9h/3h, 14mm O.D. Hot Air Tube for the Leister Weldplast S1

Blank Welding Shoe/Tip for the Leister Weldplast S1

Fillet 5/6mm Welding Shoe/Tip for the Leister Weldplast S1

V Seam 3/4mm Welding Shoe/Tip for the Leister Weldplast S1

V Seam 8/10mm Welding Shoe/Tip for the Leister Weldplast S1

Corner Welding Shoe/Tip for the Leister Weldplast S1

Leister K-8/10 EA Fillet Welding Shoe/Tip for the Leister Weldplast S1

Welding Shoe for Leister Weldplast S1

Welding Shoe for Leister Weldplast S1

Welding Shoe for Leister Weldplast S1

Welding Shoe for Leister Weldplast S1

Welding Shoe for Leister Weldplast S1

Welding Shoe for Leister Weldplast S1

Welding Shoe for Leister Weldplast S1

Welding Shoe for Leister Weldplast S1

Leister® 133.850 Hot Air Guide

Leister® Weldplast S2 45-Degree Angled Adapter (139.460)

Leister® Weldplast S2 90-Degree Angled Adapter (139.461)

Leister® 15mm (0.6") Corner Outside Seam Welding Shoe (146.651)

Leister® 30mm (1.2") Overlap Welding Shoe (145.947) for the Weldplast S2

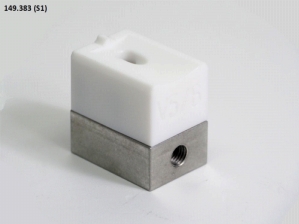

Leister® 74x50x58mm (2.91x1.96x2.3") (145.946) Blank Welding Shoe

Leister® 45x30x54mm (1.96x1.18x1.5") (145.945) Blank Welding Shoe

Leister® 8/10mm (0.13/0.4") Fillet Welding Shoe (145.944)

Leister® 20mm (0.8") Fillet Weld Welding Shoe (145.940) for the Weldplast S2.

Leister® 0.5" V-Seam & 0.98" X-Seam Welding Shoe (145.907)

Leister® 35mm (1.4") Overlap Welding Shoe (145.897)

Leister® 25mm (0.98") Overlap Welding Shoe (145.896)

Leister® 15mm (0.6") Fillet Welding Shoe (145.812)

Leister® 14mm (0.5") Corner Seam Welding Shoe/Tip. (145.811)

Leister® 20mm (0.8") Inside Corner Seam Welding Shoe/Tip. (145.488)

Extrusion Air Shoe for Weldplast S1/S2/S4

Extrusion Air Shoe for Weldplast S1/S2/S4

Extrusion Air Shoe for Weldplast S1/S2/S4

Extrusion Air Shoe for Weldplast S1/S2/S4

Extrusion Air Shoe for Weldplast S1/S2/S4

Extrusion Air Shoe for Weldplast S1/S2/S4

Extrusion Air Shoe for Weldplast S1/S2/S4

Extrusion Air Shoe for Weldplast S1/S2/S4

Extrusion Air Shoe for Weldplast S1/S2/S4

Extrusion Air Shoe for Weldplast S1/S2/S4

Extrusion Air Shoe for Weldplast S1/S2/S4

Extrusion Air Shoe for Weldplast S1/S2/S4

Extrusion Air Shoe for Weldplast S1/S2/S4

Extrusion Air Shoe for Weldplast S1/S2/S4

Extrusion Air Shoe for Weldplast S1/S2/S4

Extrusion Air Shoe for Weldplast S1/S2/S4

Extrusion Air Shoe for Weldplast S1/S2/S4

Extrusion Air Shoe for Weldplast S1/S2/S4

Extrusion Air Shoe for Weldplast S1/S2/S4

Extrusion Air Shoe for Weldplast S1/S2/S4

Preheat Nozzle for the Leister Weldplast S4

Leister 117.064 Hot Air Guide

Lesiter 117.065 Air Guide

Preheat Nozzle for the Leister Weldplast S4

Preheat Nozzle for the Leister Weldplast S4

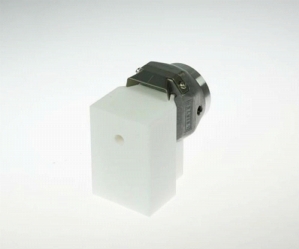

Angle Adapter for Leister Weldplast S4

Angle Adapter for Leister Weldplast S4

Leister 147.601 Angle Adapter

Extension nozzle, 5mm

3 mm. speed welding tip by Leister® (product # 106.989)

4 mm. speed welding tip by Leister® (product # 106.990)

5 mm. speed nozzle by Leister® (product # 106.991)

5.7 mm. speed welding tip by Leister® (product # 106.992)

7 mm. speed welding tip by Leister® (product # 106.993)

Tacking nozzle by Leister® (product # 106.996)

20 mm. wide slot nozzle push by Leister® (product # 106.998)

1.6 inch wide slot nozzle by Leister® (product # 106.999)

20 mm Angle Flat Slit Nozzle (product # 107.123)

40 mm. slot nozzle by Leister® (product # 107.132)

5 mm tubular nozzle by Leister®(product # 107.144) for use with Hot Jet S and Labor S.

5mm tubular welding tip (product # 100.303) for hand operated Leister Triac and Diode PID/S.

5 mm. tubular nozzle by Leister® (product # 107.154)

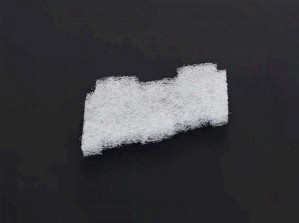

An Insulation Blanket for Leister® FUSION 1 Safekeeping

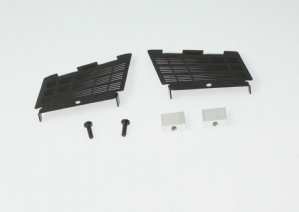

Replacement Air Filter for the Leister Weldplast S1 & S2

Tool Stand for the Leister Weldplast S1

An insulation blanket for Weldplast S1/S2 safekeeping.

An insulation blanket for Fusion 3C safekeeping.

A textile dust filter for the Weldplast S2.

Bottom air filter for Weldplast S2.

Reaches 120 Volts, 1550 Watts

Easily repair plastic bins and return them to service

Easily repair industrial fabric signs, banners, truck tarps and more.

Plastic welding is easy with the Leister plastic welding kit.

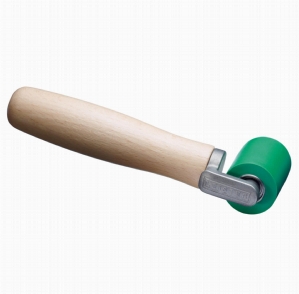

Ergonomically designed Leister’s 28mm 1.1” Pressure Roller.

Tool Rest is created for Leister Triac AT, Triac BT & Triac S models.

Storage case, for Triac AT, Triac BT, Triac S and Electron.

Leister brass wire brush used for softer materials.

The roof Seam Inspection Probe is an essential quality check tool for all roof operatives.

Leister Steel Brush Nozzle Cleaner is used to ensure the longevity of all Leister products.

Ergonomically designed, Leister 40mm Pressure Roller with Ball Bearing.

Ergonomically designed, Leister 28mm Pressure Roller.

An edge planer for T-joints from Leister - replaces 111.346.