Cut-To-Size Items are Non-Returnable!

As per our Shipping and Returns Policy, custom cuts and fabricated parts are non-returnable. If you need an over- or undersized item, note it under \"Comments\" during Checkout. Cut-to-size orders have an acceptable cut tolerance of 1/8" (0.125"), so clarify if the adjustment is to be made on the (+) or (-) side of the saw blade. Please review our full return and shipping policy here.

Measure Twice, Cut OnceSince custom cuts and fabricated parts are non-refundable, be very careful while measuring your dimensions. As each cut is nominal, even the slightest miscalculation could be costly.

How to Use a Measuring TapeExtend your tape measure several inches to find the 1 and 2 inch markers. In between the inch markers you’ll find 16 equally spaced tick marks.

Measure by counting the increments beyond the nearest inch. As the increments decrease, so does the length of the mark. For example, 1/2\" has a bigger mark than 1/4\" which has a bigger mark than 1/8\". The smallest mark follows at 1/16\". Please be aware that some measuring tapes may have even smaller increments.

Features of a Measuring Tape: Sliding End HookThe sliding end hook is designed for two different types of measurements. An outside measurement (where the hook of the tape hangs over an edge), requires the hook to slide out a bit to account for the thickness of the material. When making an inside measurement (where the hook will push up against a surface), the clip slides in, again, accounting for its thickness. The measuring tape self-adjusts to guarantee an accurate measurement (as far as the tape is concerned).

Vibratory Spring Calculator | Cut-to-Size NorPLY 1002

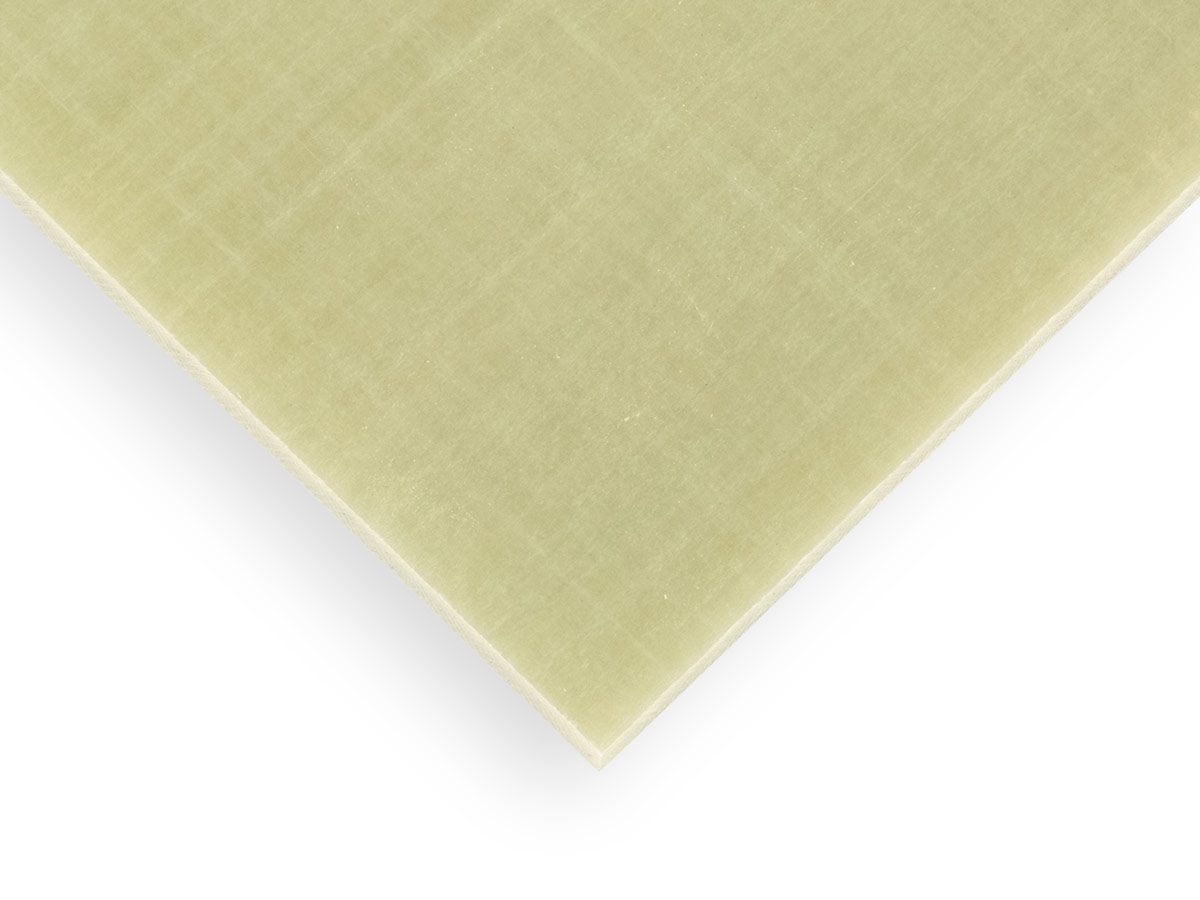

NorPLY 1002, Also Known As ScotchPly Or CyPly, Is An Epoxy Composite Used To Make Components Such As Vibratory Springs And Shocks Or Struts For Fatigue-intensive Applications.

Select your custom cut sizes:

Description

IMPORTANT: Download, fill out, and upload our spring dimensions form to specify hole diameters, placement, and more: NorPLY 1002 is a cured glass epoxy composite material designed for higher performance and longer application life. Previously known as SpringPly, SciPly, ScotchPLY, and CyPLY®, NorPLY is able to undergo many load cycles without failing and outperforms similar composite materials. NorPLY provides up to 60% part weight reduction when replacing steel components and surpasses steel for fatigue-intensive parts such as furniture springs or vibratory springs. This material offers superior energy storage capacity compared to 1060 spring steel and will not rust. It is dimensionally stable in hot, cold, wet, and dry environments and resists chemicals and corrosion. IAM-513, 517, 518, 521, and 525 are offered in spring ply, unidirectional orientation. Ordering Custom Vibratory Springs Ordering custom vibratory springs or shaker springs is straightforward: NorPLY 1002 is also available in full sheet sizes.

[DOWNLOAD SPRING DIMENSIONS FORM]

NorPLY Product Information Brochure [PDF]

- Excellent fatigue life

- High impact strength

- Resists chemicals, corrosion

- Superior energy storage capacity compared to 1060 spring steel

- Anywhere from 10% to 60% component weight reduction vs. steel

- High strength-to-weight performance

- Reduced downtime in harsh environments

- Allows for increased design options, including springs and rail joints

- High strain capability

- Low notch sensitivity

- Resistant to cleaning fluids

Specifications

Specific Gravity (g/cc): 1.85 (cured average)

Tensile Strength: 965 MPa @ 0° stress angle

Tensile Modulus: 39.3 GPa @ 0° stress angle

Flexural Modulus: 38.6 GPa @ 0° stress angle

Flexural Strength: 1150 MPa @ 0° stress angle

Hardness: Barcol 70

Compressive Strength: 880 MPa @ 0° stress angle

Linear Expansion Coefficient: 4.8 x 10-6/°F, unidirectional parallel filaments

Dielectric Constant: 5.2 @ 23°C, 1 KC

Dissipation Factor: .006 @ 23°C, 1 KC

Frequently Asked Questions

What is Interstate Advanced Materials's Shipping Policy?

Our shipping policy can be found here and orders placed for non-cut-to-size stock items typically ship within 3 working days.

Is Interstate Advanced Materials site secure?

Absolutely. Your information is passed through our https site when you make a purchase. Your Credit Card is never stored on file.