Cut-To-Size Items are Non-Returnable!

As per our Shipping and Returns Policy, custom cuts and fabricated parts are non-returnable. If you need an over- or undersized item, note it under \"Comments\" during Checkout. Cut-to-size orders have an acceptable cut tolerance of 1/8" (0.125"), so clarify if the adjustment is to be made on the (+) or (-) side of the saw blade. Please review our full return and shipping policy here.

Measure Twice, Cut OnceSince custom cuts and fabricated parts are non-refundable, be very careful while measuring your dimensions. As each cut is nominal, even the slightest miscalculation could be costly.

How to Use a Measuring TapeExtend your tape measure several inches to find the 1 and 2 inch markers. In between the inch markers you’ll find 16 equally spaced tick marks.

Measure by counting the increments beyond the nearest inch. As the increments decrease, so does the length of the mark. For example, 1/2\" has a bigger mark than 1/4\" which has a bigger mark than 1/8\". The smallest mark follows at 1/16\". Please be aware that some measuring tapes may have even smaller increments.

Features of a Measuring Tape: Sliding End HookThe sliding end hook is designed for two different types of measurements. An outside measurement (where the hook of the tape hangs over an edge), requires the hook to slide out a bit to account for the thickness of the material. When making an inside measurement (where the hook will push up against a surface), the clip slides in, again, accounting for its thickness. The measuring tape self-adjusts to guarantee an accurate measurement (as far as the tape is concerned).

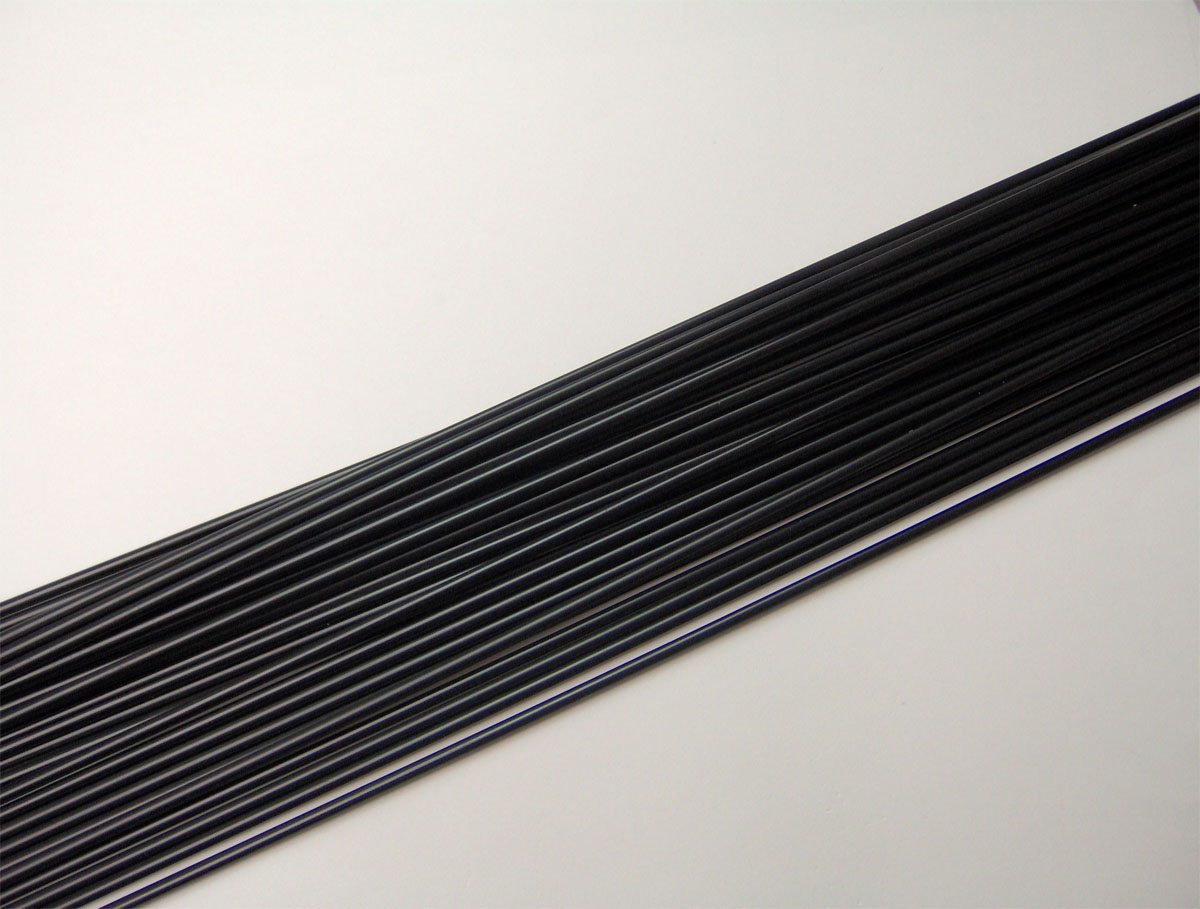

LDPE Welding Rod | Black

Low Density Polyethylene 4ft Straight Length Welding Rod

Price for 1/8"x48" - 5 Pounds Qty: 1

ESTIMATED SHIPPING TO 93001: $22.22

Description

LDPE (Low Density Polyethylene), the first developed polyethylene, is characterized by its toughness and flexibility, low heat resistance, low-temperature impact resistance, and transparency. Like the medium and high-density grades, LDPE has good resistance to chemical attack. At room temperature, it is insoluble in most organic solvents but is attacked by strong oxidizing acids. At higher temperatures, it becomes increasingly more susceptible to attack by aromatic, chlorinated and aliphatic hydrocarbons. LDPE is used for prosthetic devices and in manufacturing containers, dispensing bottles, wash bottles, tubing, plastic bags and computer components. LDPE rods are known for their low temperature flexibility, toughness and corrosion resistance. Ease of fabrication and cost effectiveness make this material the ideal choice for many applications. LDPE is not suited for applications where stiffness, high temperature resistance and structural strength are required. Polyethylene is susceptible to stress cracking when exposed to ultraviolet light and some chemicals. Wetting agents such as detergents accelerate stress cracking. Some copolymers of LDPE are available with improved stress-crack resistance. LDPE rods are used for extruded plastics. All rods are cylindrical in shape and cut to 4' lengths for shipping. Coils and additional shapes are available by request. Call 888-768-5759 for more information.

| LDPE BLACK WELDING ROD - FEET PER POUND APPROXIMATES | ||

|---|---|---|

| Approximate Feet Per Pound | ||

| 1/8" (.125") | 5/32" (.156") | 3/16" (.187) |

| ~210 ft. | ~137 ft. | ~92 ft. |

| ~52 rods | ~34 rods | ~23 rods |

| Approximate Number of 4' Rods Per Pound | ||

- FDA and NSF approval for food contact

- Available in black

- Durable

- No moisture absorption

- Good for parts that require flexibility

- Corrosion and abrasion resistant

- Very soft and pliable

- Lightweight

- Stain, odor and moisture resistant

Specifications

Frequently Asked Questions

What is Interstate Advanced Materials's Shipping Policy?

Our shipping policy can be found here and orders placed for non-cut-to-size stock items typically ship within 3 working days.

Is your site secure?

Yes, we implement a variety of security measures to maintain the safety of your personal information. Your information is protected both online and offline.